Page 96 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 96

Bearings for Mechanical Drive Turbines 77

The AMB typically includes a stator and a journal. The journal is

assembled on a portion of the rotating shaft and is surrounded by the

stator. In an eight-pole design, the stator is separated into four sectors.

Current circulates to each magnetic coil, creating a flux within each

bearing sector. This creates a magnetic force in each sector that can be

varied without affecting the other sectors, allowing independent con-

trol and physical separation.

Each sector (two poles) exerts an attractive force on the journal. Two

opposite sectors of poles at each axis are used to center the journal.

These forces, which can be varied by current, provide the stability, stiff-

ness, and damping control to the bearing.

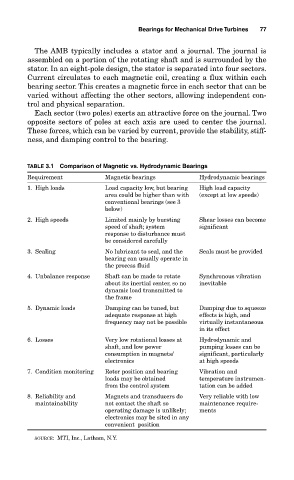

TABLE 3.1 Comparison of Magnetic vs. Hydrodynamic Bearings

Requirement Magnetic bearings Hydrodynamic bearings

1. High loads Load capacity low, but bearing High load capacity

area could be higher than with (except at low speeds)

conventional bearings (see 3

below)

2. High speeds Limited mainly by bursting Shear losses can become

speed of shaft; system significant

response to disturbance must

be considered carefully

3. Sealing No lubricant to seal, and the Seals must be provided

bearing can usually operate in

the process fluid

4. Unbalance response Shaft can be made to rotate Synchronous vibration

about its inertial center, so no inevitable

dynamic load transmitted to

the frame

5. Dynamic loads Damping can be tuned, but Damping due to squeeze

adequate response at high effects is high, and

frequency may not be possible virtually instantaneous

in its effect

6. Losses Very low rotational losses at Hydrodynamic and

shaft, and low power pumping losses can be

consumption in magnets/ significant, particularly

electronics at high speeds

7. Condition monitoring Rotor position and bearing Vibration and

loads may be obtained temperature instrumen-

from the control system tation can be added

8. Reliability and Magnets and transducers do Very reliable with low

maintainability not contact the shaft so maintenance require-

operating damage is unlikely; ments

electronics may be sited in any

convenient position

SOURCE: MTI, Inc., Latham, N.Y.