Page 286 - Steam Turbines Design, Applications, and Rerating

P. 286

Transmission Elements for High-Speed Turbomachinery 265

13.5.5 Lubricant oil containment on gear and

variable-speed units

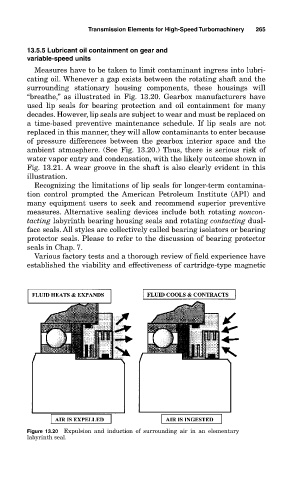

Measures have to be taken to limit contaminant ingress into lubri-

cating oil. Whenever a gap exists between the rotating shaft and the

surrounding stationary housing components, these housings will

“breathe,” as illustrated in Fig. 13.20. Gearbox manufacturers have

used lip seals for bearing protection and oil containment for many

decades. However, lip seals are subject to wear and must be replaced on

a time-based preventive maintenance schedule. If lip seals are not

replaced in this manner, they will allow contaminants to enter because

of pressure differences between the gearbox interior space and the

ambient atmosphere. (See Fig. 13.20.) Thus, there is serious risk of

water vapor entry and condensation, with the likely outcome shown in

Fig. 13.21. A wear groove in the shaft is also clearly evident in this

illustration.

Recognizing the limitations of lip seals for longer-term contamina-

tion control prompted the American Petroleum Institute (API) and

many equipment users to seek and recommend superior preventive

measures. Alternative sealing devices include both rotating noncon-

tacting labyrinth bearing housing seals and rotating contacting dual-

face seals. All styles are collectively called bearing isolators or bearing

protector seals. Please to refer to the discussion of bearing protector

seals in Chap. 7.

Various factory tests and a thorough review of field experience have

established the viability and effectiveness of cartridge-type magnetic

Figure 13.20 Expulsion and induction of surrounding air in an elementary

labyrinth seal.