Page 34 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 34

Brockenbrough_Ch01.qxd 9/29/05 4:59 PM Page 1.32

PROPERTIES OF STRUCTURAL STEELS AND EFFECTS OF STEELMAKING AND FABRICATION

1.32 CHAPTER ONE

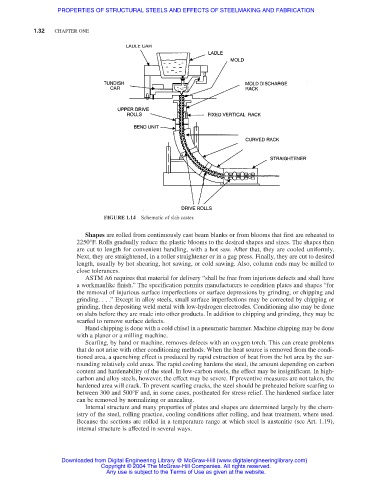

FIGURE 1.14 Schematic of slab caster.

Shapes are rolled from continuously cast beam blanks or from blooms that first are reheated to

2250°F. Rolls gradually reduce the plastic blooms to the desired shapes and sizes. The shapes then

are cut to length for convenient handling, with a hot saw. After that, they are cooled uniformly.

Next, they are straightened, in a roller straightener or in a gag press. Finally, they are cut to desired

length, usually by hot shearing, hot sawing, or cold sawing. Also, column ends may be milled to

close tolerances.

ASTM A6 requires that material for delivery “shall be free from injurious defects and shall have

a workmanlike finish.” The specification permits manufacturers to condition plates and shapes “for

the removal of injurious surface imperfections or surface depressions by grinding, or chipping and

grinding. . . .” Except in alloy steels, small surface imperfections may be corrected by chipping or

grinding, then depositing weld metal with low-hydrogen electrodes. Conditioning also may be done

on slabs before they are made into other products. In addition to chipping and grinding, they may be

scarfed to remove surface defects.

Hand chipping is done with a cold chisel in a pneumatic hammer. Machine chipping may be done

with a planer or a milling machine.

Scarfing, by hand or machine, removes defects with an oxygen torch. This can create problems

that do not arise with other conditioning methods. When the heat source is removed from the condi-

tioned area, a quenching effect is produced by rapid extraction of heat from the hot area by the sur-

rounding relatively cold areas. The rapid cooling hardens the steel, the amount depending on carbon

content and hardenability of the steel. In low-carbon steels, the effect may be insignificant. In high-

carbon and alloy steels, however, the effect may be severe. If preventive measures are not taken, the

hardened area will crack. To prevent scarfing cracks, the steel should be preheated before scarfing to

between 300 and 500°F and, in some cases, postheated for stress relief. The hardened surface later

can be removed by normalizing or annealing.

Internal structure and many properties of plates and shapes are determined largely by the chem-

istry of the steel, rolling practice, cooling conditions after rolling, and heat treatment, where used.

Because the sections are rolled in a temperature range at which steel is austenitic (see Art. 1.19),

internal structure is affected in several ways.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.