Page 10 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 10

Brockenbrough_Ch01.qxd 9/29/05 4:59 PM Page 1.8

PROPERTIES OF STRUCTURAL STEELS AND EFFECTS OF STEELMAKING AND FABRICATION

1.8 CHAPTER ONE

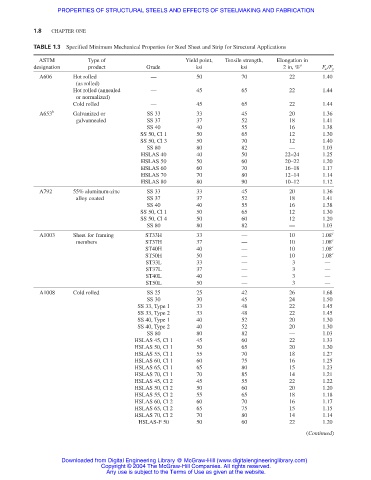

TABLE 1.3 Specified Minimum Mechanical Properties for Steel Sheet and Strip for Structural Applications

ASTM Type of Yield point, Tensile strength, Elongation in

designation product Grade ksi ksi 2 in, % a F u /F y

A606 Hot rolled — 50 70 22 1.40

(as rolled)

Hot rolled (annealed — 45 65 22 1.44

or normalized)

Cold rolled — 45 65 22 1.44

A653 b Galvanized or SS 33 33 45 20 1.36

galvannealed SS 37 37 52 18 1.41

SS 40 40 55 16 1.38

SS 50, Cl 1 50 65 12 1.30

SS 50, Cl 3 50 70 12 1.40

SS 80 80 82 — 1.03

HSLAS 40 40 50 22–24 1.25

HSLAS 50 50 60 20–22 1.20

HSLAS 60 60 70 16–18 1.17

HSLAS 70 70 80 12–14 1.14

HSLAS 80 80 90 10–12 1.12

A792 55% aluminum-zinc SS 33 33 45 20 1.36

alloy coated SS 37 37 52 18 1.41

SS 40 40 55 16 1.38

SS 50, Cl 1 50 65 12 1.30

SS 50, Cl 4 50 60 12 1.20

SS 80 80 82 — 1.03

A1003 Sheet for framing ST33H 33 — 10 1.08 c

members ST37H 37 — 10 1.08 c

ST40H 40 — 10 1.08 c

ST50H 50 — 10 1.08 c

ST33L 33 — 3 —

ST37L 37 — 3 —

ST40L 40 — 3 —

ST50L 50 — 3 —

A1008 Cold rolled SS 25 25 42 26 1.68

SS 30 30 45 24 1.50

SS 33, Type 1 33 48 22 1.45

SS 33, Type 2 33 48 22 1.45

SS 40, Type 1 40 52 20 1.30

SS 40, Type 2 40 52 20 1.30

SS 80 80 82 — 1.03

HSLAS 45, Cl 1 45 60 22 1.33

HSLAS 50, Cl 1 50 65 20 1.30

HSLAS 55, Cl 1 55 70 18 1.27

HSLAS 60, Cl 1 60 75 16 1.25

HSLAS 65, Cl 1 65 80 15 1.23

HSLAS 70, Cl 1 70 85 14 1.21

HSLAS 45, Cl 2 45 55 22 1.22

HSLAS 50, Cl 2 50 60 20 1.20

HSLAS 55, Cl 2 55 65 18 1.18

HSLAS 60, Cl 2 60 70 16 1.17

HSLAS 65, Cl 2 65 75 15 1.15

HSLAS 70, Cl 2 70 80 14 1.14

HSLAS-F 50 50 60 22 1.20

(Continued)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.