Page 6 - Sustainability in the Process Industry Integration and Optimization

P. 6

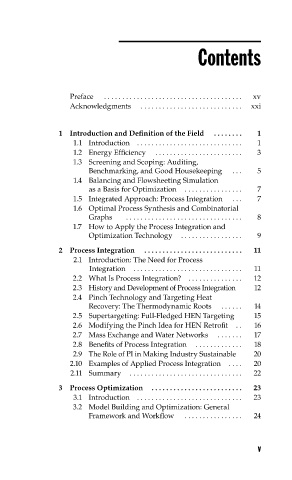

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Introduction and Definition of the Field . . . . . . . . 1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Energy Efficiency . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Screening and Scoping: Auditing,

Benchmarking, and Good Housekeeping . . . 5

1.4 Balancing and Flowsheeting Simulation

as a Basis for Optimization . . . . . . . . . . . . . . . . 7

1.5 Integrated Approach: Process Integration . . . 7

1.6 Optimal Process Synthesis and Combinatorial

Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 How to Apply the Process Integration and

Optimization Technology . . . . . . . . . . . . . . . . . 9

2 Process Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Introduction: The Need for Process

Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 What Is Process Integration? . . . . . . . . . . . . . . . 12

2.3 History and Development of Process Integration 12

2.4 Pinch Technology and Targeting Heat

Recovery: The Thermodynamic Roots . . . . . . 14

2.5 Supertargeting: Full-Fledged HEN Targeting 15

2.6 Modifying the Pinch Idea for HEN Retrofi t . . 16

2.7 Mass Exchange and Water Networks . . . . . . . 17

2.8 Benefits of Process Integration . . . . . . . . . . . . . 18

2.9 The Role of PI in Making Industry Sustainable 20

2.10 Examples of Applied Process Integration . . . . 20

2.11 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Process Optimization . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Model Building and Optimization: General

Framework and Workflow . . . . . . . . . . . . . . . . 24

v v