Page 255 - The Jet Engine

P. 255

Power plant installation

3. The position of the power plant must not affect

the efficiency of the air intake, and the exhaust gases

must be discharged clear of the aircraft and its

control surfaces. Any installation must also be such

that it produces the minimum drag effect.

4. Power plant installations are numbered from left

to right when viewed from the rear of the aircraft.

5. Supersonic aircraft usually have the power plants

buried in the aircraft for aerodynamic reasons.

Vertical lift aircraft can use either the buried installa-

tion or the podded power plant, or in some instances

both types may be combined in one aircraft (Part 18).

AIR INTAKES

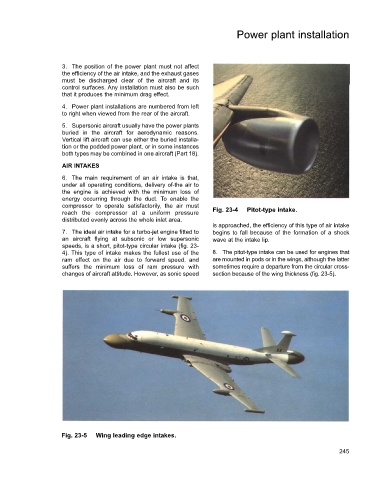

6. The main requirement of an air intake is that,

under all operating conditions, delivery of-the air to

the engine is achieved with the minimum loss of

energy occurring through the duct. To enable the

compressor to operate satisfactorily, the air must Fig. 23-4 Pitot-type intake.

reach the compressor at a uniform pressure

distributed evenly across the whole inlet area.

is approached, the efficiency of this type of air intake

7. The ideal air intake for a turbo-jet engine fitted to begins to fall because of the formation of a shock

an aircraft flying at subsonic or low supersonic wave at the intake lip.

speeds, is a short, pitot-type circular intake (fig. 23-

4). This type of intake makes the fullest use of the 8. The pitot-type intake can be used for engines that

ram effect on the air due to forward speed, and are mounted in pods or in the wings, although the latter

suffers the minimum loss of ram pressure with sometimes require a departure from the circular cross-

changes of aircraft attitude. However, as sonic speed section because of the wing thickness (fig. 23-5).

Fig. 23-5 Wing leading edge intakes.

245