Page 264 - The Jet Engine

P. 264

Maintenance

21. Before an inspection of the air intake or exhaust

system is made it must be ascertained that there Is

no possibility of the starter system being operated or

the ignition system being energized.

22. A final inspection of the engine, air intake and

exhaust system, must always be made after any

repair, adjustment or component change, to ensure

that no loose items, no matter how small, have been

left inside. Unless specific local instructions rule

otherwise, air intake and exhaust blanks or covers

should be fitted when engines are not running.

TROUBLE SHOOTING

23. The procedure for locating a fault is commonly

referred to as trouble shooting, and the requirement

under this procedure is for quick and accurate

diagnosis with the minimum associated work and the

prevention of unnecessary unit or engine removals.

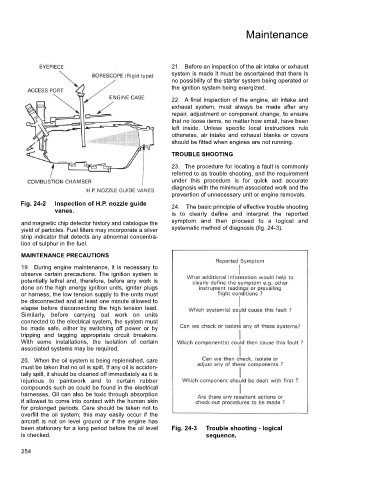

Fig. 24-2 Inspection of H.P. nozzle guide 24. The basic principle of effective trouble shooting

vanes.

is to clearly define and interpret the reported

and magnetic chip detector history and catalogue the symptom and then proceed to a logical and

yield of particles. Fuel filters may incorporate a silver systematic method of diagnosis (fig. 24-3).

strip indicator that detects any abnormal concentra-

tion of sulphur in the fuel.

MAINTENANCE PRECAUTIONS

19. During engine maintenance, it is necessary to

observe certain precautions. The ignition system is

potentially lethal and, therefore, before any work is

done on the high energy ignition units, igniter plugs

or harness, the low tension supply to the units must

be disconnected and at least one minute allowed to

elapse before disconnecting the high tension lead.

Similarly, before carrying out work on units

connected to the electrical system, the system must

be made safe, either by switching off power or by

tripping and tagging appropriate circuit breakers.

With some installations, the isolation of certain

associated systems may be required.

20. When the oil system is being replenished, care

must be taken that no oil is spilt. If any oil is acciden-

tally spilt, it should be cleaned off immediately as it is

injurious to paintwork and to certain rubber

compounds such as could be found in the electrical

harnesses, Oil can also be toxic through absorption

if allowed to come into contact with the human skin

for prolonged periods. Care should be taken not to

overfill the oil system; this may easily occur if the

aircraft is not on level ground or if the engine has

been stationary for a long period before the oil level Fig. 24-3 Trouble shooting - logical

is checked. sequence.

254