Page 299 - The Toyota Way Fieldbook

P. 299

274 THE TOYOTA WAY FIELDBOOK

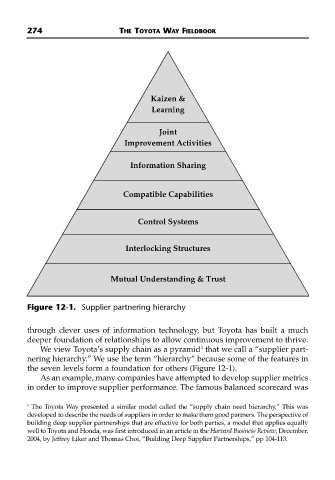

Kaizen &

Learning

Joint

Improvement Activities

Information Sharing

Compatible Capabilities

Control Systems

Interlocking Structures

Mutual Understanding & Trust

Figure 12-1. Supplier partnering hierarchy

through clever uses of information technology, but Toyota has built a much

deeper foundation of relationships to allow continuous improvement to thrive.

We view Toyota’s supply chain as a pyramid that we call a “supplier part-

3

nering hierarchy.” We use the term “hierarchy” because some of the features in

the seven levels form a foundation for others (Figure 12-1).

As an example, many companies have attempted to develop supplier metrics

in order to improve supplier performance. The famous balanced scorecard was

3

The Toyota Way presented a similar model called the “supply chain need hierarchy.” This was

developed to describe the needs of suppliers in order to make them good partners. The perspective of

building deep supplier partnerships that are effective for both parties, a model that applies equally

well to Toyota and Honda, was first introduced in an article in the Harvard Business Review, December,

2004, by Jeffrey Liker and Thomas Choi, “Building Deep Supplier Partnerships,” pp 104-113.