Page 113 - Welding of Aluminium and its Alloys

P. 113

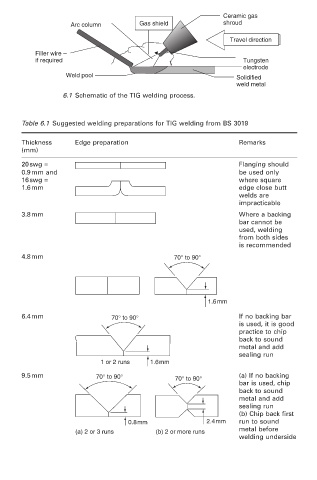

Ceramic gas

Arc column Gas shield shroud

Travel direction

Filler wire –

if required Tungsten

electrode

Weld pool Solidified

weld metal

6.1 Schematic of the TIG welding process.

Table 6.1 Suggested welding preparations for TIG welding from BS 3019

Thickness Edge preparation Remarks

(mm)

20swg = Flanging should

0.9mm and be used only

16swg = where square

1.6mm edge close butt

welds are

impracticable

3.8mm Where a backing

bar cannot be

used, welding

from both sides

is recommended

4.8mm 70° to 90°

1.6 mm

6.4mm 70° to 90° If no backing bar

is used, it is good

practice to chip

back to sound

metal and add

sealing run

1 or 2 runs 1.6 mm

9.5mm 70° to 90° 70° to 90° (a) If no backing

bar is used, chip

back to sound

metal and add

sealing run

(b) Chip back first

0.8 mm 2.4 mm run to sound

(a) 2 or 3 runs (b) 2 or more runs metal before

welding underside