Page 206 - Welding of Aluminium and its Alloys

P. 206

Welding procedure and welder approval 189

PE

PC

PG PF

PD

PB

PA

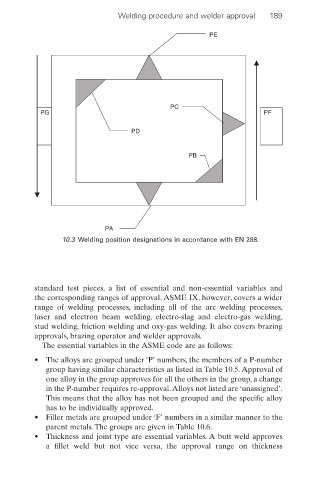

10.3 Welding position designations in accordance with EN 288.

standard test pieces, a list of essential and non-essential variables and

the corresponding ranges of approval. ASME IX, however, covers a wider

range of welding processes, including all of the arc welding processes,

laser and electron beam welding, electro-slag and electro-gas welding,

stud welding, friction welding and oxy-gas welding. It also covers brazing

approvals, brazing operator and welder approvals.

The essential variables in the ASME code are as follows:

• The alloys are grouped under ‘P’ numbers, the members of a P-number

group having similar characteristics as listed in Table 10.5. Approval of

one alloy in the group approves for all the others in the group, a change

in the P-number requires re-approval.Alloys not listed are ‘unassigned’.

This means that the alloy has not been grouped and the specific alloy

has to be individually approved.

• Filler metals are grouped under ‘F’ numbers in a similar manner to the

parent metals. The groups are given in Table 10.6.

• Thickness and joint type are essential variables. A butt weld approves

a fillet weld but not vice versa, the approval range on thickness