Page 38 - Welding of Aluminium and its Alloys

P. 38

30 The welding of aluminium and its alloys

Small gap – high dilution

Large gap – low dilution

2.15 Effect of variations in root gap.

Electrode

Shallow Weld preparation

penetration surface Deep

penetration

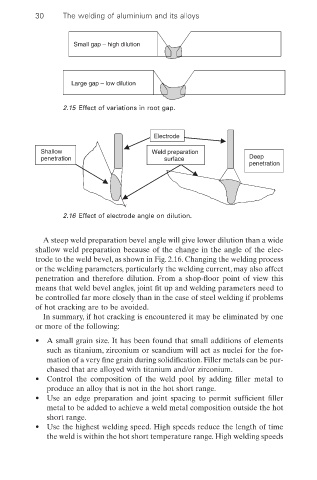

2.16 Effect of electrode angle on dilution.

A steep weld preparation bevel angle will give lower dilution than a wide

shallow weld preparation because of the change in the angle of the elec-

trode to the weld bevel, as shown in Fig. 2.16. Changing the welding process

or the welding parameters, particularly the welding current, may also affect

penetration and therefore dilution. From a shop-floor point of view this

means that weld bevel angles, joint fit up and welding parameters need to

be controlled far more closely than in the case of steel welding if problems

of hot cracking are to be avoided.

In summary, if hot cracking is encountered it may be eliminated by one

or more of the following:

• A small grain size. It has been found that small additions of elements

such as titanium, zirconium or scandium will act as nuclei for the for-

mation of a very fine grain during solidification. Filler metals can be pur-

chased that are alloyed with titanium and/or zirconium.

• Control the composition of the weld pool by adding filler metal to

produce an alloy that is not in the hot short range.

• Use an edge preparation and joint spacing to permit sufficient filler

metal to be added to achieve a weld metal composition outside the hot

short range.

• Use the highest welding speed. High speeds reduce the length of time

the weld is within the hot short temperature range. High welding speeds