Page 77 - Welding of Aluminium and its Alloys

P. 77

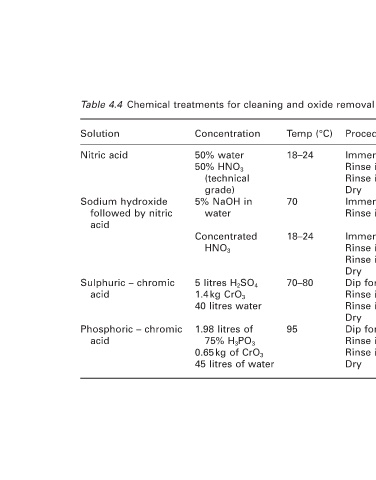

Procedure Purpose Container material Removal of thin oxide film Stainless steel Immerse 15min for fusion welding Rinse in cold water Rinse in hot water Dry Removal of thick oxide film Mild steel Immerse 10 to 60s for all welding and Stainless steel Rinse in cold water brazing operations Imme

Chemical treatments for cleaning and oxide removal

Temp (°C) 18–24 70 18–24 70–80 95

Concentration 50% water 50% HNO 3 (technical grade) 5% NaOH in water Concentrated HNO 3 5 litres H 2SO 4 1.4kg CrO 3 40 litres water 1.98 litres of 75% H 3PO 3 0.65kg of CrO 3 45 litres of water

Table 4.4 Solution Nitric acid Sodium hydroxide followed by nitric acid Sulphuric – chromic acid Phosphoric – chromic acid