Page 32 - The Mechatronics Handbook

P. 32

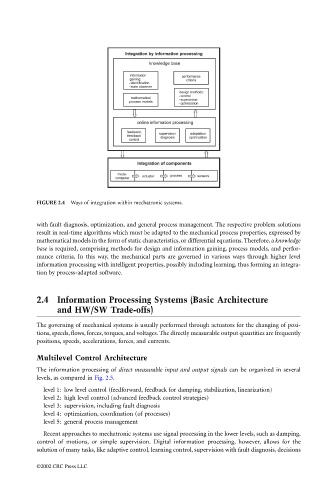

FIGURE 2.4 Ways of integration within mechatronic systems.

with fault diagnosis, optimization, and general process management. The respective problem solutions

result in real-time algorithms which must be adapted to the mechanical process properties, expressed by

mathematical models in the form of static characteristics, or differential equations. Therefore, a knowledge

base is required, comprising methods for design and information gaining, process models, and perfor-

mance criteria. In this way, the mechanical parts are governed in various ways through higher level

information processing with intelligent properties, possibly including learning, thus forming an integra-

tion by process-adapted software.

2.4 Information Processing Systems (Basic Architecture

and HW/SW Trade-offs)

The governing of mechanical systems is usually performed through actuators for the changing of posi-

tions, speeds, flows, forces, torques, and voltages. The directly measurable output quantities are frequently

positions, speeds, accelerations, forces, and currents.

Multilevel Control Architecture

The information processing of direct measurable input and output signals can be organized in several

levels, as compared in Fig. 2.5.

level 1: low level control (feedforward, feedback for damping, stabilization, linearization)

level 2: high level control (advanced feedback control strategies)

level 3: supervision, including fault diagnosis

level 4: optimization, coordination (of processes)

level 5: general process management

Recent approaches to mechatronic systems use signal processing in the lower levels, such as damping,

control of motions, or simple supervision. Digital information processing, however, allows for the

solution of many tasks, like adaptive control, learning control, supervision with fault diagnosis, decisions

©2002 CRC Press LLC