Page 40 - Toyota Under Fire

P. 40

THE MOST ADMIRED COMP ANY IN THE WORLD

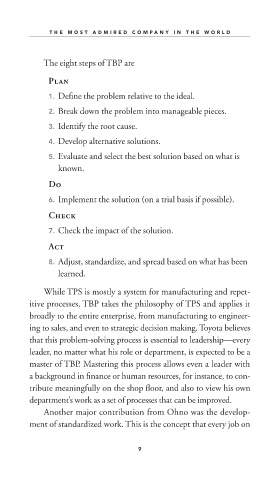

The eight steps of TBP are

Plan

1. Define the problem relative to the ideal.

2. Break down the problem into manageable pieces.

3. Identify the root cause.

4. Develop alternative solutions.

5. Evaluate and select the best solution based on what is

known.

Do

6. Implement the solution (on a trial basis if possible).

Check

7. Check the impact of the solution.

Act

8. Adjust, standardize, and spread based on what has been

learned.

While TPS is mostly a system for manufacturing and repet-

itive processes, TBP takes the philosophy of TPS and applies it

broadly to the entire enterprise, from manufacturing to engineer-

ing to sales, and even to strategic decision making. Toyota believes

that this problem-solving process is essential to leadership—every

leader, no matter what his role or department, is expected to be a

master of TBP. Mastering this process allows even a leader with

a background in finance or human resources, for instance, to con-

tribute meaningfully on the shop floor, and also to view his own

department’s work as a set of processes that can be improved.

Another major contribution from Ohno was the develop-

ment of standardized work. This is the concept that every job on

9