Page 261 - Understanding Automotive Electronics

P. 261

2735 | CH 7 Page 248 Tuesday, March 10, 1998 1:15 PM

7 DIGITAL ENGINE CONTROL SYSTEM

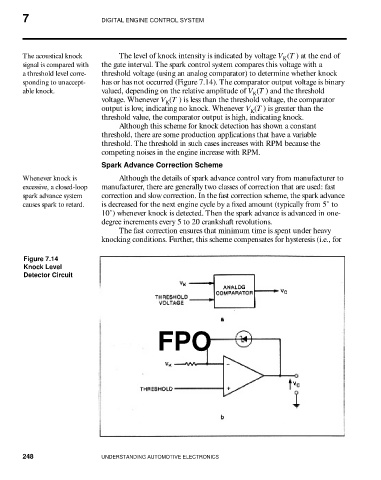

The acoustical knock The level of knock intensity is indicated by voltage V (T ) at the end of

K

signal is compared with the gate interval. The spark control system compares this voltage with a

a threshold level corre- threshold voltage (using an analog comparator) to determine whether knock

sponding to unaccept- has or has not occurred (Figure 7.14). The comparator output voltage is binary

able knock. valued, depending on the relative amplitude of V (T ) and the threshold

K

voltage. Whenever V (T ) is less than the threshold voltage, the comparator

K

output is low, indicating no knock. Whenever V (T ) is greater than the

K

threshold value, the comparator output is high, indicating knock.

Although this scheme for knock detection has shown a constant

threshold, there are some production applications that have a variable

threshold. The threshold in such cases increases with RPM because the

competing noises in the engine increase with RPM.

Spark Advance Correction Scheme

Whenever knock is Although the details of spark advance control vary from manufacturer to

excessive, a closed-loop manufacturer, there are generally two classes of correction that are used: fast

spark advance system correction and slow correction. In the fast correction scheme, the spark advance

causes spark to retard. is decreased for the next engine cycle by a fixed amount (typically from 5˚ to

10˚) whenever knock is detected. Then the spark advance is advanced in one-

degree increments every 5 to 20 crankshaft revolutions.

The fast correction ensures that minimum time is spent under heavy

knocking conditions. Further, this scheme compensates for hysteresis (i.e., for

Figure 7.14

Knock Level

Detector Circuit

FPO

248 UNDERSTANDING AUTOMOTIVE ELECTRONICS