Page 187 - Understanding Flight

P. 187

CH07_Anderson 7/25/01 9:00 AM Page 174

174 CHAPTER SEVEN

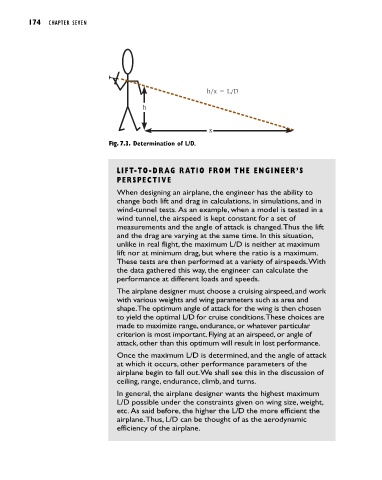

h/x = L/D

h

x

Fig. 7.3. Determination of L/D.

LIFT-TO-DRAG RATIO FROM THE ENGINEER’S

PERSPECTIVE

When designing an airplane, the engineer has the ability to

change both lift and drag in calculations, in simulations, and in

wind-tunnel tests. As an example, when a model is tested in a

wind tunnel, the airspeed is kept constant for a set of

measurements and the angle of attack is changed.Thus the lift

and the drag are varying at the same time. In this situation,

unlike in real flight, the maximum L/D is neither at maximum

lift nor at minimum drag, but where the ratio is a maximum.

These tests are then performed at a variety of airspeeds.With

the data gathered this way, the engineer can calculate the

performance at different loads and speeds.

The airplane designer must choose a cruising airspeed, and work

with various weights and wing parameters such as area and

shape.The optimum angle of attack for the wing is then chosen

to yield the optimal L/D for cruise conditions.These choices are

made to maximize range, endurance, or whatever particular

criterion is most important. Flying at an airspeed, or angle of

attack, other than this optimum will result in lost performance.

Once the maximum L/D is determined, and the angle of attack

at which it occurs, other performance parameters of the

airplane begin to fall out.We shall see this in the discussion of

ceiling, range, endurance, climb, and turns.

In general, the airplane designer wants the highest maximum

L/D possible under the constraints given on wing size, weight,

etc. As said before, the higher the L/D the more efficient the

airplane.Thus, L/D can be thought of as the aerodynamic

efficiency of the airplane.