Page 169 - Using ANSYS for Finite Element Analysis Dynamic, Probabilistic, Design and Heat Transfer Analysis

P. 169

156 • using ansys for finite eLement anaLysis

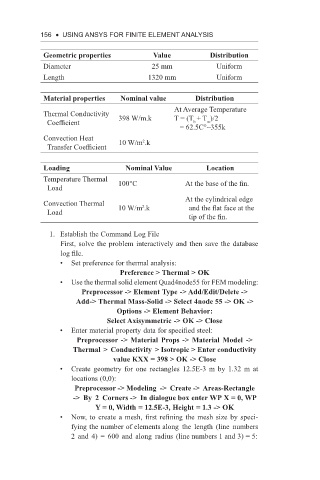

Geometric properties Value Distribution

Diameter 25 mm Uniform

Length 1320 mm Uniform

Material properties Nominal value Distribution

At Average Temperature

Thermal Conductivity 398 W/m.k T = (T + T )/2

Coefficient b ∞

= 62.5C°~355k

Convection Heat 10 W/m .k

2

Transfer Coefficient

Loading Nominal Value Location

Temperature Thermal 100°C At the base of the fin.

Load

At the cylindrical edge

Convection Thermal 10 W/m .k and the flat face at the

2

Load

tip of the fin.

1. Establish the Command Log File

First, solve the problem interactively and then save the database

log file.

• Set preference for thermal analysis:

Preference > Thermal > OK

• Use the thermal solid element Quad4node55 for FEM modeling:

Preprocessor -> Element Type -> Add/Edit/Delete ->

Add-> Thermal Mass-Solid -> Select 4node 55 -> OK ->

Options -> Element Behavior:

Select Axisymmetric -> OK -> Close

• Enter material property data for specified steel:

Preprocessor -> Material Props -> Material Model ->

Thermal > Conductivity > Isotropic > Enter conductivity

value KXX = 398 > OK -> Close

• Create geometry for one rectangles 12.5E-3 m by 1.32 m at

locations (0,0):

Preprocessor -> Modeling -> Create -> Areas-Rectangle

-> By 2 Corners -> In dialogue box enter WP X = 0, WP

Y = 0, Width = 12.5E-3, Height = 1.3 -> OK

• Now, to create a mesh, first refining the mesh size by speci-

fying the number of elements along the length (line numbers

2 and 4) = 600 and along radius (line numbers 1 and 3) = 5: