Page 232 - Valve Selection Handbook

P. 232

Rupture Discs 219

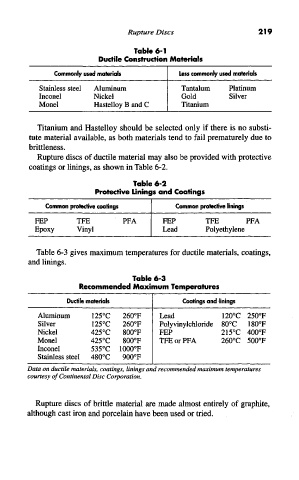

Table 6-1

Ductile Construction Materials

Commonly used materials Less commonly used materials

Stainless steel Aluminum Tantalum Platinum

Inconel Nickel Gold Silver

Monel Hastelloy B and C Titanium

Titanium and Hastelloy should be selected only if there is no substi-

tute material available, as both materials tend to fail prematurely due to

brittleness.

Rupture discs of ductile material may also be provided with protective

coatings or linings, as shown in Table 6-2.

Table 6-2

Protective Linings and Coatings

Common protective coatings Common protective linings

FEP TFE PFA FEP TFE PFA

Epoxy Vinyl Lead Polyethylene

Table 6-3 gives maximum temperatures for ductile materials, coatings,

and linings.

Table 6-3

Recommended Maximum Temperatures

Ductile materials Coatings and linings

Aluminum 125°C 260°F Lead 120°C 250°F

Silver 125°C 260°F Polyvinylchloride 80°C 180°F

Nickel 425°C 800°F FEP 215°C 400°F

Monel 425°C 800°F TFE or PFA 260°C 500°F

Inconel 535°C 1000°F

Stainless steel 480°C 900°F

Data on ductile materials, coatings, linings and recommended maximum temperatures

courtesy of Continental Disc Corporation.

Rupture discs of brittle material are made almost entirely of graphite,

although cast iron and porcelain have been used or tried.