Page 7 - Valve Selection Handbook

P. 7

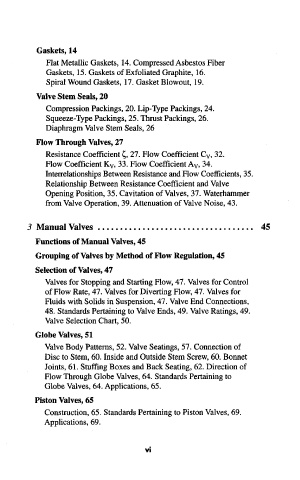

Gaskets, 14

Flat Metallic Gaskets, 14. Compressed Asbestos Fiber

Gaskets, 15. Gaskets of Exfoliated Graphite, 16.

Spiral Wound Gaskets, 17. Gasket Blowout, 19.

Valve Stem Seals, 20

Compression Packings, 20. Lip-Type Packings, 24.

Squeeze-Type Packings, 25. Thrust Packings, 26.

Diaphragm Valve Stem Seals, 26

Flow Through Valves, 27

Resistance Coefficient £, 27. Flow Coefficient C v, 32.

Flow Coefficient K v, 33. Flow Coefficient A v, 34.

Interrelationships Between Resistance and Row Coefficients, 35.

Relationship Between Resistance Coefficient and Valve

Opening Position, 35. Cavitation of Valves, 37. Waterhammer

from Valve Operation, 39. Attenuation of Valve Noise, 43.

3 Manual Valves 45

Functions of Manual Valves, 45

Grouping of Valves by Method of Flow Regulation, 45

Selection of Valves, 47

Valves for Stopping and Starting Flow, 47. Valves for Control

of Flow Rate, 47. Valves for Diverting Flow, 47. Valves for

Fluids with Solids in Suspension, 47. Valve End Connections,

48. Standards Pertaining to Valve Ends, 49. Valve Ratings, 49.

Valve Selection Chart, 50.

Globe Valves, 51

Valve Body Patterns, 52. Valve Seatings, 57. Connection of

Disc to Stem, 60. Inside and Outside Stem Screw, 60. Bonnet

Joints, 61. Stuffing Boxes and Back Seating, 62. Direction of

Flow Through Globe Valves, 64. Standards Pertaining to

Globe Valves, 64. Applications, 65.

Piston Valves, 65

Construction, 65. Standards Pertaining to Piston Valves, 69.

Applications, 69.

VI