Page 128 - Vogel's TEXTBOOK OF QUANTITATIVE CHEMICAL ANALYSIS

P. 128

3 COMMON APPARATUS AND BASIC TECHNIQUES

desiccator should be lightly coated with white Vaseline or a special grease in

order to make it air-tight; too much grease rnay permit the lid to slide.

There is however controversy regarding the effectiveness of desiccators. If

the lid is briefly removed from a desiccator then it rnay take as long as two

hours to remove the atmospheric moisture thus introduced, and to re-establish

the dry atmosphere: during this period, a hygroscopic substance rnay actually

gain in weight while in the desiccator. It is therefore advisable that any substance

which is to be weighed should be kept in a vesse1 with as tightly fitting a lid as

possible while it is in the desiccator.

The problem of the cooling of hot vessels within a desiccator is also important.

A crucible which has been strongly ignited and immediately transferred to a

desiccator rnay not have attained room temperature even after one hour. The

situation can be improved by allowing the crucible to cool for a few minutes

before transferring to the desiccator, and then a cooling time of 20-25 minutes

is usually adequate. The inclusion in the desiccator of a metal block

(e.g. aluminium), upon which the crucible rnay be stood, is also helpful in

ensuring the attainment of temperature equilibrium.

When a hot object, such as a crucible, is placed in a desiccator, about

5-10 seconds should elapse for the air to become heated and expand before

putting the cover in place. When re-opening, the cover should be slid open very

gradually in order to prevent any sudden inrush of air due to the partial

vacuum which exists owing to the cooling of the expanded gas content of the

desiccator, and thus prevent material being blown out of the crucible.

A desiccator is frequently also employed for the thorough drying of solids

for analysis and for other purposes. Its efficient operation depends upon the

condition of the desiccant; the latter should therefore be renewed at frequent

intervals, particularly if its drying capacity is low. For dealing with large

quantities of solid a vacuum desiccator is advisable.

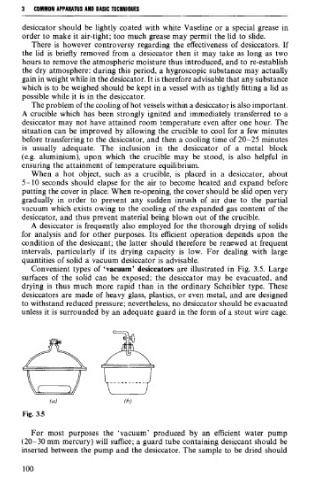

Convenient types of 'vacuum' desiccators are illustrated in Fig. 3.5. Large

surfaces of the solid can be exposed; the desiccator rnay be evacuated, and

drying is thus much more rapid than in the ordinary Scheibler type. These

desiccators are made of heavy glass, plastics, or even metal, and are designed

to withstand reduced pressure; nevertheless, no desiccator should be evacuated

unless it is surrounded by an adequate guard in the form of a stout wire cage.

lu)

Fig. 3.5

For most purposes the 'vacuum' produced by an efficient water pump

(20-30 mm mercury) will suffice; a guard tube containing desiccant should be

inserted between the pump and the desiccator. The sample to be dried should