Page 172 - Materials Chemistry, Second Edition

P. 172

CAT3525_C06.qxd 1/29/2005 9:56 AM Page 143

Recycling Solid Wastes 143

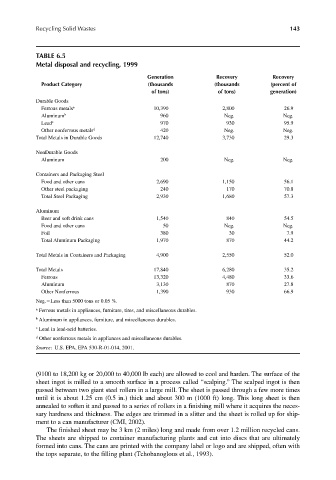

TABLE 6.5

Metal disposal and recycling, 1999

Generation Recovery Recovery

Product Category (thousands (thousands (percent of

of tons) of tons) generation)

Durable Goods

Ferrous metals a 10,390 2,800 26.9

Aluminum b 960 Neg. Neg.

Lead c 970 930 95.9

Other nonferrous metals d 420 Neg. Neg.

Total Metals in Durable Goods 12,740 3,730 29.3

NonDurable Goods

Aluminum 200 Neg. Neg.

Containers and Packaging Steel

Food and other cans 2,690 1,150 56.1

Other steel packaging 240 170 70.8

Total Steel Packaging 2,930 1,680 57.3

Aluminum

Beer and soft drink cans 1,540 840 54.5

Food and other cans 50 Neg. Neg.

Foil 380 30 7.9

Total Aluminum Packaging 1,970 870 44.2

Total Metals in Containers and Packaging 4,900 2,550 52.0

Total Metals 17,840 6,280 35.2

Ferrous 13,320 4,480 33.6

Aluminum 3,130 870 27.8

Other Nonferrous 1,390 930 66.9

Neg. Less than 5000 tons or 0.05 %.

a Ferrous metals in appliances, furniture, tires, and miscellaneous durables.

b Aluminum in appliances, furniture, and miscellaneous durables.

c Lead in lead-acid batteries.

d Other nonferrous metals in appliances and miscellaneous durables.

Source: U.S. EPA, EPA 530-R-01-014, 2001.

(9100 to 18,200 kg or 20,000 to 40,000 lb each) are allowed to cool and harden. The surface of the

sheet ingot is milled to a smooth surface in a process called “scalping.” The scalped ingot is then

passed between two giant steel rollers in a large mill. The sheet is passed through a few more times

until it is about 1.25 cm (0.5 in.) thick and about 300 m (1000 ft) long. This long sheet is then

annealed to soften it and passed to a series of rollers in a finishing mill where it acquires the neces-

sary hardness and thickness. The edges are trimmed in a slitter and the sheet is rolled up for ship-

ment to a can manufacturer (CMI, 2002).

The finished sheet may be 3 km (2 miles) long and made from over 1.2 million recycled cans.

The sheets are shipped to container manufacturing plants and cut into discs that are ultimately

formed into cans. The cans are printed with the company label or logo and are shipped, often with

the tops separate, to the filling plant (Tchobanoglous et al., 1993).