Page 350 - Materials Chemistry, Second Edition

P. 350

CAT3525_C10.qxd 1/31/2005 12:00 PM Page 321

The Sanitary Landfill 321

Passive Gas

Venting vent flare Barrier

trench wall

E E E

E

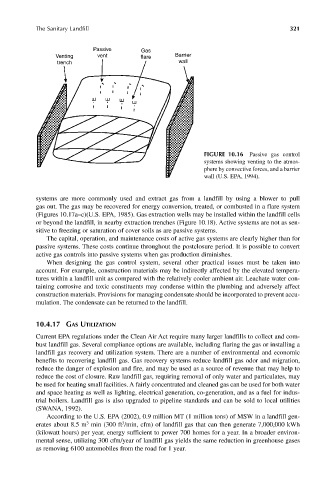

FIGURE 10.16 Passive gas control

systems showing venting to the atmos-

phere by convective forces, and a barrier

wall (U.S. EPA, 1994).

systems are more commonly used and extract gas from a landfill by using a blower to pull

gas out. The gas may be recovered for energy conversion, treated, or combusted in a flare system

(Figures 10.17a–c)(U.S. EPA, 1985). Gas extraction wells may be installed within the landfill cells

or beyond the landfill, in nearby extraction trenches (Figure 10.18). Active systems are not as sen-

sitive to freezing or saturation of cover soils as are passive systems.

The capital, operation, and maintenance costs of active gas systems are clearly higher than for

passive systems. These costs continue throughout the postclosure period. It is possible to convert

active gas controls into passive systems when gas production diminishes.

When designing the gas control system, several other practical issues must be taken into

account. For example, construction materials may be indirectly affected by the elevated tempera-

tures within a landfill unit as compared with the relatively cooler ambient air. Leachate water con-

taining corrosive and toxic constituents may condense within the plumbing and adversely affect

construction materials. Provisions for managing condensate should be incorporated to prevent accu-

mulation. The condensate can be returned to the landfill.

10.4.17 GAS UTILIZATION

Current EPA regulations under the Clean Air Act require many larger landfills to collect and com-

bust landfill gas. Several compliance options are available, including flaring the gas or installing a

landfill gas recovery and utilization system. There are a number of environmental and economic

benefits to recovering landfill gas. Gas recovery systems reduce landfill gas odor and migration,

reduce the danger of explosion and fire, and may be used as a source of revenue that may help to

reduce the cost of closure. Raw landfill gas, requiring removal of only water and particulates, may

be used for heating small facilities. A fairly concentrated and cleaned gas can be used for both water

and space heating as well as lighting, electrical generation, co-generation, and as a fuel for indus-

trial boilers. Landfill gas is also upgraded to pipeline standards and can be sold to local utilities

(SWANA, 1992).

According to the U.S. EPA (2002), 0.9 million MT (1 million tons) of MSW in a landfill gen-

3

3

erates about 8.5 m min (300 ft /min, cfm) of landfill gas that can then generate 7,000,000 kWh

(kilowatt hours) per year, energy sufficient to power 700 homes for a year. In a broader environ-

mental sense, utilizing 300 cfm/year of landfill gas yields the same reduction in greenhouse gases

as removing 6100 automobiles from the road for 1 year.