Page 140 - Wastewater Solids Incineration Systems

P. 140

Heat Recovery and Reuse 107

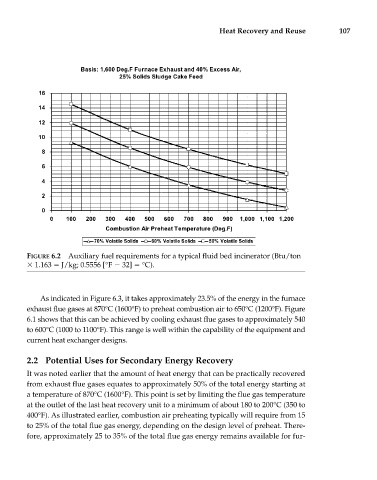

FIGURE 6.2 Auxiliary fuel requirements for a typical fluid bed incinerator (Btu/ton

1.163 J/kg; 0.5556 [°F 32] °C).

As indicated in Figure 6.3, it takes approximately 23.5% of the energy in the furnace

exhaust flue gases at 870°C (1600°F) to preheat combustion air to 650°C (1200°F). Figure

6.1 shows that this can be achieved by cooling exhaust flue gases to approximately 540

to 600°C (1000 to 1100°F). This range is well within the capability of the equipment and

current heat exchanger designs.

2.2 Potential Uses for Secondary Energy Recovery

It was noted earlier that the amount of heat energy that can be practically recovered

from exhaust flue gases equates to approximately 50% of the total energy starting at

a temperature of 870°C (1600°F). This point is set by limiting the flue gas temperature

at the outlet of the last heat recovery unit to a minimum of about 180 to 200°C (350 to

400°F). As illustrated earlier, combustion air preheating typically will require from 15

to 25% of the total flue gas energy, depending on the design level of preheat. There-

fore, approximately 25 to 35% of the total flue gas energy remains available for fur-