Page 296 - Wastewater Solids Incineration Systems

P. 296

Incinerator Maintenance 257

(a) (b)

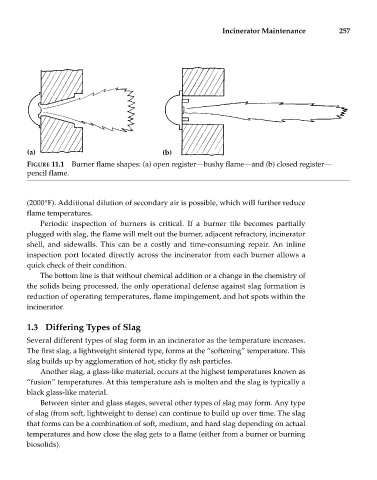

FIGURE 11.1 Burner flame shapes: (a) open register—bushy flame—and (b) closed register—

pencil flame.

(2000°F). Additional dilution of secondary air is possible, which will further reduce

flame temperatures.

Periodic inspection of burners is critical. If a burner tile becomes partially

plugged with slag, the flame will melt out the burner, adjacent refractory, incinerator

shell, and sidewalls. This can be a costly and time-consuming repair. An inline

inspection port located directly across the incinerator from each burner allows a

quick check of their condition.

The bottom line is that without chemical addition or a change in the chemistry of

the solids being processed, the only operational defense against slag formation is

reduction of operating temperatures, flame impingement, and hot spots within the

incinerator.

1.3 Differing Types of Slag

Several different types of slag form in an incinerator as the temperature increases.

The first slag, a lightweight sintered type, forms at the “softening” temperature. This

slag builds up by agglomeration of hot, sticky fly ash particles.

Another slag, a glass-like material, occurs at the highest temperatures known as

“fusion” temperatures. At this temperature ash is molten and the slag is typically a

black glass-like material.

Between sinter and glass stages, several other types of slag may form. Any type

of slag (from soft, lightweight to dense) can continue to build up over time. The slag

that forms can be a combination of soft, medium, and hard slag depending on actual

temperatures and how close the slag gets to a flame (either from a burner or burning

biosolids).