Page 201 - Water and wastewater engineering

P. 201

5-4 WATER AND WASTEWATER ENGINEERING

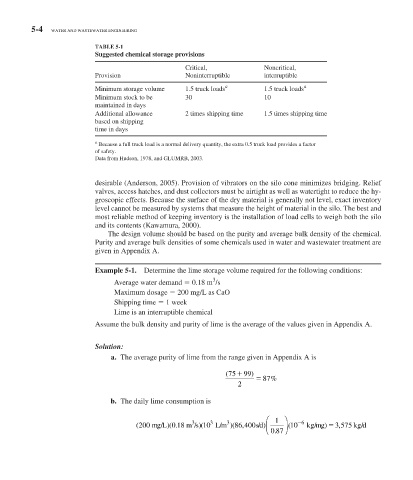

TABLE 5-1

Suggested chemical storage provisions

Critical, Noncritical,

Provision Noninterruptible interruptible

a a

Minimum storage volume 1.5 truck loads 1.5 truck loads

Minimum stock to be 30 10

maintained in days

Additional allowance 2 times shipping time 1.5 times shipping time

based on shipping

time in days

a

Because a full truck load is a normal delivery quantity, the extra 0.5 truck load provides a factor

of safety.

Data from Hudson, 1978, and GLUMRB, 2003.

desirable (Anderson, 2005). Provision of vibrators on the silo cone minimizes bridging. Relief

valves, access hatches, and dust collectors must be airtight as well as watertight to reduce the hy-

groscopic effects. Because the surface of the dry material is generally not level, exact inventory

level cannot be measured by systems that measure the height of material in the silo. The best and

most reliable method of keeping inventory is the installation of load cells to weigh both the silo

and its contents (Kawamura, 2000).

The design volume should be based on the purity and average bulk density of the chemical.

Purity and average bulk densities of some chemicals used in water and wastewater treatment are

given in Appendix A.

Example 5-1. Determine the lime storage volume required for the following conditions:

3

Average water demand 0.18 m /s

Maximum dosage 200 mg/L as CaO

Shipping time 1 week

Lime is an interruptible chemical

Assume the bulk density and purity of lime is the average of the values given in Appendix A.

Solution:

a. The average purity of lime from the range given in Appendix A is

(75 99 )

87%

2

b. The daily lime consumption is

⎛ 1 ⎞

3

3

(200 mg/L )(0 18 m /s )(10 L/m 3 )(86 400s/d ) ⎜ ⎟ ( 10 6 kg/mg ) 3 575 kg/d

,

.

,

.

⎝ 0 087⎠