Page 218 - Water and wastewater engineering

P. 218

CHEMICAL HANDLING AND STORAGE 5-21

Vent

Dust collector

Manhole

Large radius elbow

Cylindrical

lime

Pneumatic

silo

conveying pipe Load cell

Bin activator

Bin gate

10 cm dia. fill connection

to bulk delivery truck

Flexible coupling

Gravimetric dry

chemical feeder

Overflow

Slaker

Plastic milk Slaker

crate lined with discharge To venturl

hardware cloth Drain

eductor

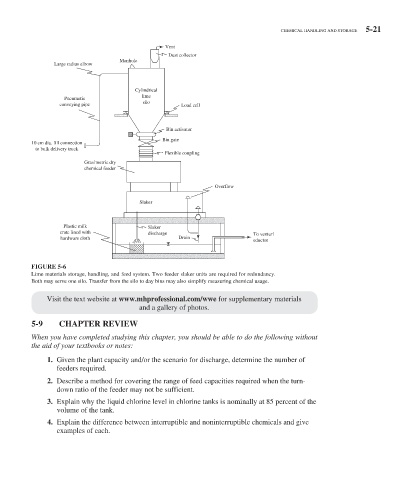

FIGURE 5-6

Lime materials storage, handling, and feed system. Two feeder slaker units are required for redundancy.

Both may serve one silo. Transfer from the silo to day bins may also simplify measuring chemical usage.

Visit the text website at www.mhprofessional.com/wwe for supplementary materials

and a gallery of photos.

5-9 CHAPTER REVIEW

When you have completed studying this chapter, you should be able to do the following without

the aid of your textbooks or notes:

1. Given the plant capacity and/or the scenario for discharge, determine the number of

feeders required.

2. Describe a method for covering the range of feed capacities required when the turn-

down ratio of the feeder may not be sufficient.

3. Explain why the liquid chlorine level in chlorine tanks is nominally at 85 percent of the

volume of the tank.

4. Explain the difference between interruptible and noninterruptible chemicals and give

examples of each.