Page 250 - Water and wastewater engineering

P. 250

COAGULATION AND FLOCCULATION 6-27

The focus of this discussion is on the following three mixing alternatives: in-line mechanical

mixing, in-line static mixing, and mechanical mixing in stirred tanks.

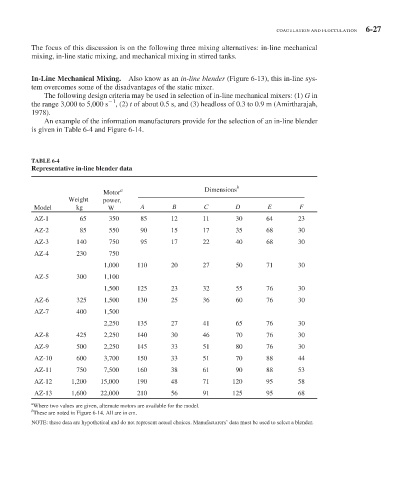

In-Line Mechanical Mixing. Also know as an in-line blender ( Figure 6-13 ), this in-line sys-

tem overcomes some of the disadvantages of the static mixer.

The following design criteria may be used in selection of in-line mechanical mixers: (1) G in

1

the range 3,000 to 5,000 s , (2) t of about 0.5 s, and (3) headloss of 0.3 to 0.9 m (Amirtharajah,

1978).

An example of the information manufacturers provide for the selection of an in-line blender

is given in Table 6-4 and Figure 6-14 .

TABLE 6-4

Representative in-line blender data

b

Motor a Dimensions

Weight

power,

Model kg W A B C D E F

AZ-1 65 350 85 12 11 30 64 23

AZ-2 85 550 90 15 17 35 68 30

AZ-3 140 750 95 17 22 40 68 30

AZ-4 230 750

1,000 110 20 27 50 71 30

AZ-5 300 1,100

1,500 125 23 32 55 76 30

AZ-6 325 1,500 130 25 36 60 76 30

AZ-7 400 1,500

2,250 135 27 41 65 76 30

AZ-8 425 2,250 140 30 46 70 76 30

AZ-9 500 2,250 145 33 51 80 76 30

AZ-10 600 3,700 150 33 51 70 88 44

AZ-11 750 7,500 160 38 61 90 88 53

AZ-12 1,200 15,000 190 48 71 120 95 58

AZ-13 1,600 22,000 210 56 91 125 95 68

a

Where two values are given, alternate motors are available for the model.

b

These are noted in Figure 6-14. All are in cm.

NOTE: these data are hypothetical and do not represent actual choices. Manufacturers’ data must be used to select a blender.