Page 21 - Welding Robots Technology, System Issues, and Applications

P. 21

5

Introduction and Overview

Consequently, the task of automating the welding operation is to reproduce the

experienced and skilled manual welder in terms of positioning the welding torch,

and controlling the welding parameters. That means availability of databases that

register known cases, from where initial conditions can be selected, along with

type of shielding gases and wires. That means also the capacity to observe the

ongoing process and adjust or adapt the controlling parameters in accordance with

the desired results. And finally, the possibility of holding the welding torch and

move it in a precise and controlled way. Therefore, as previously mentioned,

automating the welding process is a mixture of robotics research, control systems

research, sensor research, sensor fusion and artificial intelligence.

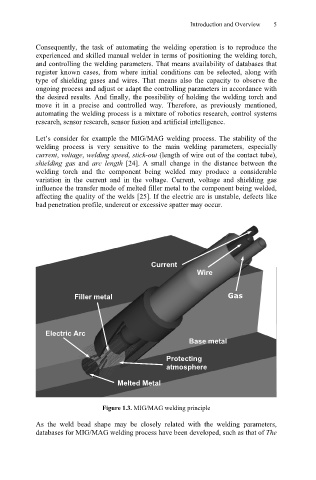

Let’s consider for example the MIG/MAG welding process. The stability of the

welding process is very sensitive to the main welding parameters, especially

current, voltage, welding speed, stick-out (length of wire out of the contact tube),

shielding gas and arc length [24]. A small change in the distance between the

welding torch and the component being welded may produce a considerable

variation in the current and in the voltage. Current, voltage and shielding gas

influence the transfer mode of melted filler metal to the component being welded,

affecting the quality of the welds [25]. If the electric arc is unstable, defects like

bad penetration profile, undercut or excessive spatter may occur.

Current

Wire

Filler metal Gas

Electric Arc

Base metal

Protecting

atmosphere

Melted Metal

Figure 1.3. MIG/MAG welding principle

As the weld bead shape may be closely related with the welding parameters,

databases for MIG/MAG welding process have been developed, such as that of The