Page 128 - Well Control for Completions and Interventions

P. 128

120 Well Control for Completions and Interventions

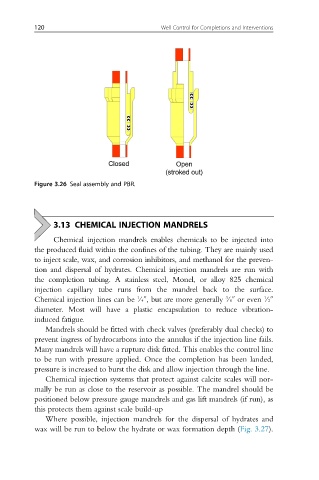

Figure 3.26 Seal assembly and PBR.

3.13 CHEMICAL INJECTION MANDRELS

Chemical injection mandrels enables chemicals to be injected into

the produced fluid within the confines of the tubing. They are mainly used

to inject scale, wax, and corrosion inhibitors, and methanol for the preven-

tion and dispersal of hydrates. Chemical injection mandrels are run with

the completion tubing. A stainless steel, Monel, or alloy 825 chemical

injection capillary tube runs from the mandrel back to the surface.

Chemical injection lines can be /4v,but aremoregenerally /8v or even /2v

1

3

1

diameter. Most will have a plastic encapsulation to reduce vibration-

induced fatigue.

Mandrels should be fitted with check valves (preferably dual checks) to

prevent ingress of hydrocarbons into the annulus if the injection line fails.

Many mandrels will have a rupture disk fitted. This enables the control line

to be run with pressure applied. Once the completion has been landed,

pressure is increased to burst the disk and allow injection through the line.

Chemical injection systems that protect against calcite scales will nor-

mally be run as close to the reservoir as possible. The mandrel should be

positioned below pressure gauge mandrels and gas lift mandrels (if run), as

this protects them against scale build-up

Where possible, injection mandrels for the dispersal of hydrates and

wax will be run to below the hydrate or wax formation depth (Fig. 3.27).