Page 187 - Well Control for Completions and Interventions

P. 187

Well Control Surface Equipment 179

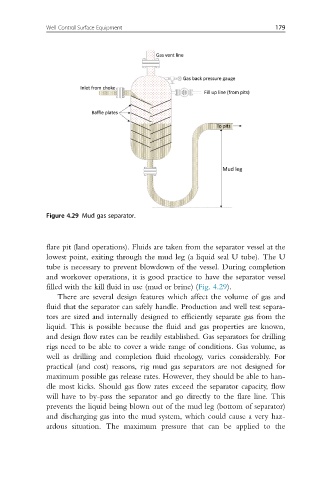

Figure 4.29 Mud gas separator.

flare pit (land operations). Fluids are taken from the separator vessel at the

lowest point, exiting through the mud leg (a liquid seal U tube). The U

tube is necessary to prevent blowdown of the vessel. During completion

and workover operations, it is good practice to have the separator vessel

filled with the kill fluid in use (mud or brine) (Fig. 4.29).

There are several design features which affect the volume of gas and

fluid that the separator can safely handle. Production and well test separa-

tors are sized and internally designed to efficiently separate gas from the

liquid. This is possible because the fluid and gas properties are known,

and design flow rates can be readily established. Gas separators for drilling

rigs need to be able to cover a wide range of conditions. Gas volume, as

well as drilling and completion fluid rheology, varies considerably. For

practical (and cost) reasons, rig mud gas separators are not designed for

maximum possible gas release rates. However, they should be able to han-

dle most kicks. Should gas flow rates exceed the separator capacity, flow

will have to by-pass the separator and go directly to the flare line. This

prevents the liquid being blown out of the mud leg (bottom of separator)

and discharging gas into the mud system, which could cause a very haz-

ardous situation. The maximum pressure that can be applied to the