Page 221 - Well Control for Completions and Interventions

P. 221

214 Well Control for Completions and Interventions

losses by pumping a kill pill into the casing at surface and waiting for it to

reach the formation. The entire wellbore volume must be lost to the for-

mation before the kill pill can work. For this reason, at least twice the cir-

culating volume should be considered as a minimum requirement for

brine quantity. In many instances, where losses are continual or difficult

to control, considerably more fluid will be required.

5.10.6 Brine volume summary

Consider preparing a simple spreadsheet itemizing and quantifying brine

volume requirement. The spreadsheet can incorporate simple tubing and

casing capacity calculations. The total volume would include:

1. Wellbore capacity

2. Surface lines

3. Holding tanks

4. Filtration unit capacity

5. Contingency.

5.11 ALTERNATIVES TO BRINE

For fluid to be classified as a well control barrier, it must be moni-

tored. In practical terms this means the fluid level must reach the surface,

where it can be observed. If the reservoir pressure is too low to support

the hydrostatic pressure that results from a full column of water based

fluid, then a lower density alternative must be used if a fluid barrier is

used. Nonwater based alternatives can be used across a range of lighter

than water densities (Table 5.8).

Under exceptional circumstances, mud is used as a completion and

workover fluid, normally where there are major safety concerns associated

with well control. For example, in the Chevron operated Tengiz field

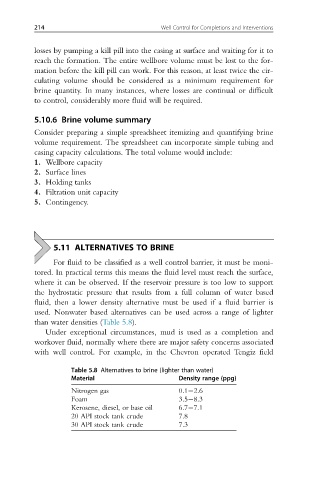

Table 5.8 Alternatives to brine (lighter than water)

Material Density range (ppg)

Nitrogen gas 0.1 2.6

Foam 3.5 8.3

Kerosene, diesel, or base oil 6.7 7.1

20 API stock tank crude 7.8

30 API stock tank crude 7.3