Page 319 - Mechanical Behavior of Materials

P. 319

320 Chapter 7 Yielding and Fracture under Combined Stresses

σ

(a) ductile 3 yield

σ

2

fracture

σ

1

σ

3 yield

(b) brittle

σ

2

σ

1

fracture

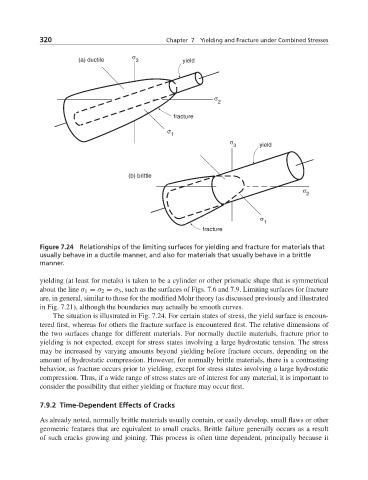

Figure 7.24 Relationships of the limiting surfaces for yielding and fracture for materials that

usually behave in a ductile manner, and also for materials that usually behave in a brittle

manner.

yielding (at least for metals) is taken to be a cylinder or other prismatic shape that is symmetrical

about the line σ 1 = σ 2 = σ 3 , such as the surfaces of Figs. 7.6 and 7.9. Limiting surfaces for fracture

are, in general, similar to those for the modified Mohr theory (as discussed previously and illustrated

in Fig. 7.21), although the boundaries may actually be smooth curves.

The situation is illustrated in Fig. 7.24. For certain states of stress, the yield surface is encoun-

tered first, whereas for others the fracture surface is encountered first. The relative dimensions of

the two surfaces change for different materials. For normally ductile materials, fracture prior to

yielding is not expected, except for stress states involving a large hydrostatic tension. The stress

may be increased by varying amounts beyond yielding before fracture occurs, depending on the

amount of hydrostatic compression. However, for normally brittle materials, there is a contrasting

behavior, as fracture occurs prior to yielding, except for stress states involving a large hydrostatic

compression. Thus, if a wide range of stress states are of interest for any material, it is important to

consider the possibility that either yielding or fracture may occur first.

7.9.2 Time-Dependent Effects of Cracks

As already noted, normally brittle materials usually contain, or easily develop, small flaws or other

geometric features that are equivalent to small cracks. Brittle failure generally occurs as a result

of such cracks growing and joining. This process is often time dependent, principally because it