Page 114 - Introduction to Marine Engineering

P. 114

Feed systems 101

Economiser

"**~1 1 I* 1

^nF

.« ,jr

-**-

-If- h\

," Boiler

(Condenser} v, 71-

*Alr X Recirculating

and line ' Drains <-<>wP«*sure

vapour Air cooler heat er Superheater

.

ejector

tJu _/

High pressure

heater

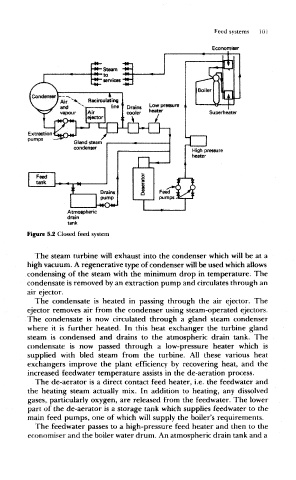

Figure 5.2 Closed feed system

The steam turbine will exhaust into the condenser which will be at a

high vacuum. A regenerative type of condenser will be used which allows

condensing of the steam with the minimum drop in temperature. The

condensate is removed by an extraction pump and circulates through an

air ejector.

The condensate is heated in passing through the air ejector. The

ejector removes air from the condenser using steam-ope rated ejectors.

The condensate is now circulated through a gland steam condenser

where it is further heated. In this heat exchanger the turbine gland

steam is condensed and drains to the atmospheric drain tank. The

condensate is now passed through a low-pressure heater which is

supplied with bled steam from the turbine. All these various heat

exchangers improve the plant efficiency by recovering heat, and the

increased feedwater temperature assists in the de-aeration process.

The de-aerator is a direct contact feed heater, i.e. the feedwater and

the heating steam actually mix. In addition to heating, any dissolved

gases, particularly oxygen, are released from the feedwater. The lower

part of the de-aerator is a storage tank which supplies feedwater to the

main feed pumps, one of which will supply the boiler's requirements.

The feedwater passes to a high-pressure feed heater and then to the

economiser and the boiler water drum. An atmospheric drain tank and a