Page 118 - Introduction to Marine Engineering

P. 118

Feed systems 105

Exhaust steam

Condenser

shell

Air and vapour

suction

Extraction

pump suction

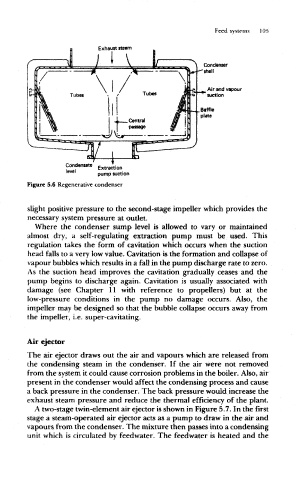

Figure 5.6 Regenerative condenser

slight positive pressure to the second-stage impeller which provides the

necessary system pressure at outlet.

Where the condenser sump level is allowed to vary or maintained

almost dry, a self-regulating extraction pump must be used. This

regulation takes the form of cavitation which occurs when the suction

head falls to a very low value. Cavitation is the formation and collapse of

vapour bubbles which results in a fall in the pump discharge rate to zero.

As the suction head improves the cavitation gradually ceases and the

pump begins to discharge again. Cavitation is usually associated with

damage (see Chapter 11 with reference to propellers) but at the

low-pressure conditions in the pump no damage occurs. Also, the

impeller may be designed so that the bubble collapse occurs away from

the impeller, i.e. super-cavitating.

Air ejector

The air ejector draws out the air and vapours which are released from

the condensing steam in the condenser. If the air were not removed

from the system it could cause corrosion problems in the boiler. Also, air

present in the condenser would affect the condensing process and cause

a back pressure in the condenser. The back pressure would increase the

exhaust steam pressure and reduce the thermal efficiency of the plant.

A two-stage twin-element air ejector is shown in Figure 5.7. In the first

stage a steam-operated air ejector acts as a pump to draw in the air and

vapours from the condenser. The mixture then passes into a condensing

unit which is circulated by feedwater. The feedwater is heated and the