Page 120 - Introduction to Marine Engineering

P. 120

Feed systems 107

The gland steam condenser collects steam, vapour and air from the

turbine gland steam system. These returns are cooled by the circulating

feed water and the steam is condensed. The condensate is returned to

the system via a loop seal or some form of steam trap and any air present

Is discharged into the atmosphere. The feedwater passes through

U-tubes within the shell of the unit.

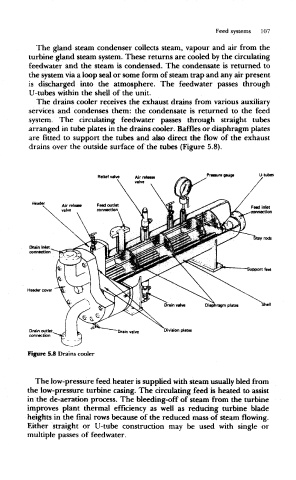

The drains cooler receives the exhaust drains from various auxiliary

services and condenses them: the condensate is returned to the feed

system. The circulating feedwater passes through straight tubes

arranged in tube plates in the drains cooler. Baffles or diaphragm plates

are fitted to support the tubes and also direct the flow of the exhaust

drains over the outside surface of the tubes (Figure 5.8).

Premire gauge U-tubes

Relief valve

Header

Drain valve Diaphragm plates

Division plates

Figure 5.8 Drains cooler

The low-pressure feed heater is supplied with steam usually bled from

the low-pressure turbine casing. The circulating feed is heated to assist

in the de-aeration process. The bleeding-off of steam from the turbine

improves plant thermal efficiency as well as reducing turbine blade

heights in the final rows because of the reduced mass of steam flowing.

Either straight or U-tube construction may be used with single or

multiple passes of feedwater.