Page 89 - Introduction to Marine Engineering

P. 89

76 Boilers

process is much quicker. Design arrangements are flexible, efficiency is

high and the feedwater has a good natural circulation. These are some

of the many reasons why the watertube boiler has replaced the firetube

boiler as the major steam producer.

Early watertube boilers used a single drum. Headers were connected

to the drum by short, bent pipes with straight tubes between the headers.

The hot gases from the furnace passed over the tubes, often in a single

pass,

A later development was the bent tube design. This boiler has two

drums, an integral furnace and is often referred to as the 'D' type

because of its shape (Figure 4.2). The furnace is at the side of the two

drums and is surrounded on all sides by walls of tubes. These waterwall

tubes are connected either to upper and lower headers or a lower header

and the steam drum. Upper headers are connected by return tubes to

the steam drum. Between the steam drum and the smaller water drum

below, large numbers of smaller-diameter generating tubes are fitted.

Floor tubes

Refractory

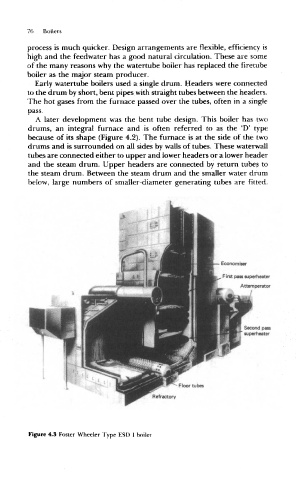

Figure 4.3 Foster Wheeler Type ESD I boiler