Page 100 - Materials Chemistry, Second Edition

P. 100

Life Cycle Evaluation for Alkaline Battery Waste Treatment 81

To assess the impacts (LCIA), the following methods are used: CML 2000 and

ReCiPe endpoint (H) in the SimaPro software.

5.3 PROCESS DESCRIPTION

5.3.1 deScription of the SeLection proceSS

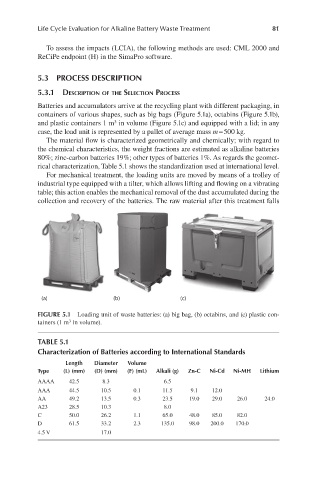

Batteries and accumulators arrive at the recycling plant with different packaging, in

containers of various shapes, such as big bags (Figure 5.1a), octabins (Figure 5.1b),

3

and plastic containers 1 m in volume (Figure 5.1c) and equipped with a lid; in any

case, the load unit is represented by a pallet of average mass m = 500 kg.

The material flow is characterized geometrically and chemically; with regard to

the chemical characteristics, the weight fractions are estimated as alkaline batteries

80%; zinc-carbon batteries 19%; other types of batteries 1%. As regards the geomet-

rical characterization, Table 5.1 shows the standardization used at international level.

For mechanical treatment, the loading units are moved by means of a trolley of

industrial type equipped with a tilter, which allows lifting and flowing on a vibrating

table; this action enables the mechanical removal of the dust accumulated during the

collection and recovery of the batteries. The raw material after this treatment falls

(a) (b) (c)

FIGURE 5.1 Loading unit of waste batteries: (a) big bag, (b) octabins, and (c) plastic con-

tainers (1 m in volume).

3

TABLE 5.1

Characterization of Batteries according to International Standards

Length Diameter Volume

Type (L) (mm) (D) (mm) (F) (mL) Alkali (g) Zn-C Ni-Cd Ni-MH Lithium

AAAA 42.5 8.3 6.5

AAA 44.5 10.5 0.1 11.5 9.1 12.0

AA 49.2 13.5 0.3 23.5 19.0 29.0 26.0 24.0

A23 28.5 10.3 8.0

C 50.0 26.2 1.1 65.0 48.0 85.0 82.0

D 61.5 33.2 2.3 135.0 98.0 200.0 170.0

4.5 V 17.0