Page 412 - Moving the Earth_ The Workbook of Excavation

P. 412

BLASTING AND TUNNELING

9.12 THE WORK

Line Drilling. In line drilling, a single row of holes, usually 3-inch or less, is drilled along the

edge, either from top to bottom, or in benches. Spacing is very close, from 2 to 4 hole diameters.

These holes are left empty. They create a line of weakness along which the rock should be

sheared by the preliminary blast.

The back row of primary holes may be closer to the line than the normal between-row interval,

and may be more closely spaced and lightly loaded than other rows.

This method is best suited to formations with a minimum of bedding planes, joints, and other

weaknesses which may affect breakage more than the line of holes. Weak-bedded rock may

respond satisfactorily if its planes are nearly at right angles with the proposed slope, or exactly

parallel to it.

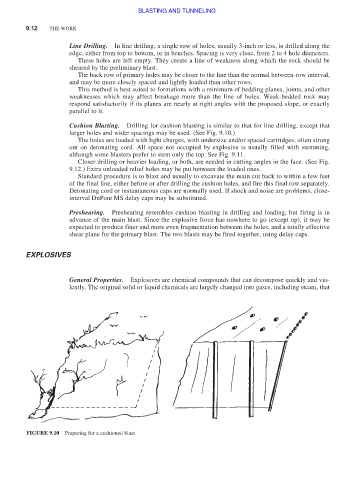

Cushion Blasting. Drilling for cushion blasting is similar to that for line drilling, except that

larger holes and wider spacings may be used. (See Fig. 9.10.)

The holes are loaded with light charges, with undersize and/or spaced cartridges, often strung

out on detonating cord. All space not occupied by explosive is usually filled with stemming,

although some blasters prefer to stem only the top. See Fig. 9.11.

Closer drilling or heavier loading, or both, are needed in cutting angles in the face. (See Fig.

9.12.) Extra unloaded relief holes may be put between the loaded ones.

Standard procedure is to blast and usually to excavate the main cut back to within a few feet

of the final line, either before or after drilling the cushion holes, and fire this final row separately.

Detonating cord or instantaneous caps are normally used. If shock and noise are problems, close-

interval DuPont MS delay caps may be substituted.

Preshearing. Preshearing resembles cushion blasting in drilling and loading, but firing is in

advance of the main blast. Since the explosive force has nowhere to go (except up), it may be

expected to produce finer and more even fragmentation between the holes, and a totally effective

shear plane for the primary blast. The two blasts may be fired together, using delay caps.

EXPLOSIVES

General Properties. Explosives are chemical compounds that can decompose quickly and vio-

lently. The original solid or liquid chemicals are largely changed into gases, including steam, that

FIGURE 9.10 Preparing for a cushioned blast.