Page 411 - Moving the Earth_ The Workbook of Excavation

P. 411

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.11

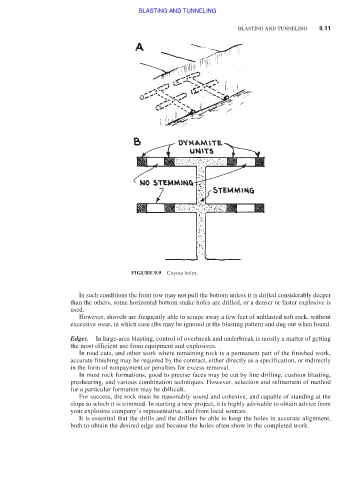

FIGURE 9.9 Coyote holes.

In such conditions the front row may not pull the bottom unless it is drilled considerably deeper

than the others, some horizontal bottom snake holes are drilled, or a denser or faster explosive is

used.

However, shovels are frequently able to scrape away a few feet of unblasted soft rock, without

excessive wear, in which case ribs may be ignored in the blasting pattern and dug out when found.

Edges. In large-area blasting, control of overbreak and underbreak is mostly a matter of getting

the most efficient use from equipment and explosives.

In road cuts, and other work where remaining rock is a permanent part of the finished work,

accurate finishing may be required by the contract, either directly as a specification, or indirectly

in the form of nonpayment or penalties for excess removal.

In most rock formations, good to precise faces may be cut by line drilling, cushion blasting,

preshearing, and various combination techniques. However, selection and refinement of method

for a particular formation may be difficult.

For success, the rock must be reasonably sound and cohesive, and capable of standing at the

slope to which it is trimmed. In starting a new project, it is highly advisable to obtain advice from

your explosive company’s representative, and from local sources.

It is essential that the drills and the drillers be able to keep the holes in accurate alignment,

both to obtain the desired edge and because the holes often show in the completed work.