Page 443 - Moving the Earth_ The Workbook of Excavation

P. 443

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.43

Skullcrackers eliminate the danger and nuisance of secondary blasting, but they cause problems

of their own. Rock chips fly from 50 to 200 feet, and they make the area around the operation one

of continuous danger. The operator’s station on the crane must be protected with wire mesh or

bulletproof glass, and signals must be arranged to stop the work when the area must be entered by

others.

Some rock breaks very well on impact, and others do not. If breakage is good, the rock can be

readily reached by the crane, and other operations are not unreasonably delayed by it, this is a

good method.

Some quarries or pits keep a drop ball stored on a crane at all times, and may use it continu-

ously or only occasionally. Gravel pits may push boulders aside until there are too many around,

and then put a ball on one of the draglines or clamshells for a day or two. Rock breaking may be

done on days when the pit is shut down, to avoid interference.

Plug and Feathers. Rock may be broken by first drilling, then inserting a device in the hole that

can be caused to expand until it breaks the rock. The Egyptians used dry wood plugs, which they

supplied with water until they swelled and broke the rock. Now we use wedges or jacks to obtain

the same result.

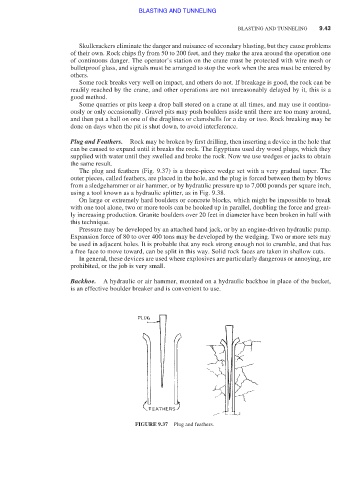

The plug and feathers (Fig. 9.37) is a three-piece wedge set with a very gradual taper. The

outer pieces, called feathers, are placed in the hole, and the plug is forced between them by blows

from a sledgehammer or air hammer, or by hydraulic pressure up to 7,000 pounds per square inch,

using a tool known as a hydraulic splitter, as in Fig. 9.38.

On large or extremely hard boulders or concrete blocks, which might be impossible to break

with one tool alone, two or more tools can be hooked up in parallel, doubling the force and great-

ly increasing production. Granite boulders over 20 feet in diameter have been broken in half with

this technique.

Pressure may be developed by an attached hand jack, or by an engine-driven hydraulic pump.

Expansion force of 80 to over 400 tons may be developed by the wedging. Two or more sets may

be used in adjacent holes. It is probable that any rock strong enough not to crumble, and that has

a free face to move toward, can be split in this way. Solid rock faces are taken in shallow cuts.

In general, these devices are used where explosives are particularly dangerous or annoying, are

prohibited, or the job is very small.

Backhoe. A hydraulic or air hammer, mounted on a hydraulic backhoe in place of the bucket,

is an effective boulder breaker and is convenient to use.

FIGURE 9.37 Plug and feathers.