Page 461 - Moving the Earth_ The Workbook of Excavation

P. 461

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.61

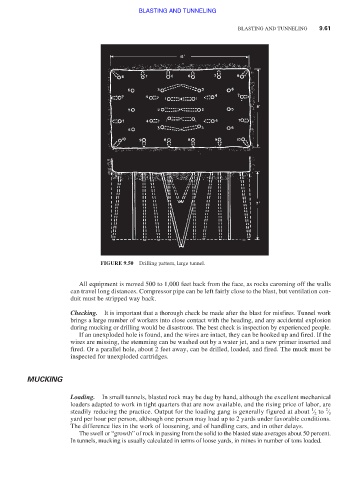

FIGURE 9.50 Drilling pattern, large tunnel.

All equipment is moved 500 to 1,000 feet back from the face, as rocks caroming off the walls

can travel long distances. Compressor pipe can be left fairly close to the blast, but ventilation con-

duit must be stripped way back.

Checking. It is important that a thorough check be made after the blast for misfires. Tunnel work

brings a large number of workers into close contact with the heading, and any accidental explosion

during mucking or drilling would be disastrous. The best check is inspection by experienced people.

If an unexploded hole is found, and the wires are intact, they can be hooked up and fired. If the

wires are missing, the stemming can be washed out by a water jet, and a new primer inserted and

fired. Or a parallel hole, about 2 feet away, can be drilled, loaded, and fired. The muck must be

inspected for unexploded cartridges.

MUCKING

Loading. In small tunnels, blasted rock may be dug by hand, although the excellent mechanical

loaders adapted to work in tight quarters that are now available, and the rising price of labor, are

1 2

steadily reducing the practice. Output for the loading gang is generally figured at about ⁄ 2 to ⁄ 3

yard per hour per person, although one person may load up to 2 yards under favorable conditions.

The difference lies in the work of loosening, and of handling cars, and in other delays.

The swell or “growth” of rock in passing from the solid to the blasted state averages about 50 percent.

In tunnels, mucking is usually calculated in terms of loose yards, in mines in number of tons loaded.