Page 98 - Moving the Earth_ The Workbook of Excavation

P. 98

SURVEYS AND MEASUREMENTS

2.48 THE WORK

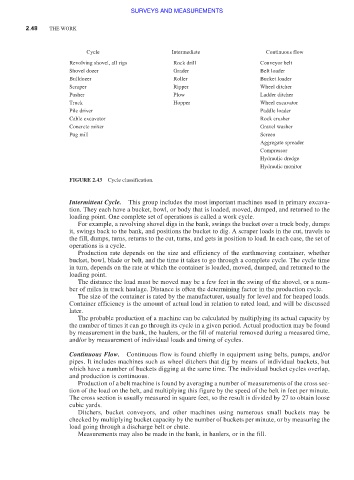

Cycle Intermediate Continuous flow

Revolving shovel, all rigs Rock drill Conveyor belt

Shovel dozer Grader Belt loader

Bulldozer Roller Bucket loader

Scraper Ripper Wheel ditcher

Pusher Plow Ladder ditcher

Truck Hopper Wheel excavator

Pile driver Paddle loader

Cable excavator Rock crusher

Concrete mixer Gravel washer

Pug mill Screen

Aggregate spreader

Compressor

Hydraulic dredge

Hydraulic monitor

FIGURE 2.43 Cycle classification.

Intermittent Cycle. This group includes the most important machines used in primary excava-

tion. They each have a bucket, bowl, or body that is loaded, moved, dumped, and returned to the

loading point. One complete set of operations is called a work cycle.

For example, a revolving shovel digs in the bank, swings the bucket over a truck body, dumps

it, swings back to the bank, and positions the bucket to dig. A scraper loads in the cut, travels to

the fill, dumps, turns, returns to the cut, turns, and gets in position to load. In each case, the set of

operations is a cycle.

Production rate depends on the size and efficiency of the earthmoving container, whether

bucket, bowl, blade or belt, and the time it takes to go through a complete cycle. The cycle time

in turn, depends on the rate at which the container is loaded, moved, dumped, and returned to the

loading point.

The distance the load must be moved may be a few feet in the swing of the shovel, or a num-

ber of miles in truck haulage. Distance is often the determining factor in the production cycle.

The size of the container is rated by the manufacturer, usually for level and for heaped loads.

Container efficiency is the amount of actual load in relation to rated load, and will be discussed

later.

The probable production of a machine can be calculated by multiplying its actual capacity by

the number of times it can go through its cycle in a given period. Actual production may be found

by measurement in the bank, the haulers, or the fill of material removed during a measured time,

and/or by measurement of individual loads and timing of cycles.

Continuous Flow. Continuous flow is found chiefly in equipment using belts, pumps, and/or

pipes. It includes machines such as wheel ditchers that dig by means of individual buckets, but

which have a number of buckets digging at the same time. The individual bucket cycles overlap,

and production is continuous.

Production of a belt machine is found by averaging a number of measurements of the cross sec-

tion of the load on the belt, and multiplying this figure by the speed of the belt in feet per minute.

The cross section is usually measured in square feet, so the result is divided by 27 to obtain loose

cubic yards.

Ditchers, bucket conveyors, and other machines using numerous small buckets may be

checked by multiplying bucket capacity by the number of buckets per minute, or by measuring the

load going through a discharge belt or chute.

Measurements may also be made in the bank, in haulers, or in the fill.