Page 105 -

P. 105

AERATION AND AIR STRIPPING 5.21

Treated air

Contaminated

acFirveathed

air

Source

water

Packed

column

Clean

Heating Blower Spent activated

a r ~

element carbon to

regeneration or

disposal

Blower

Treated

water

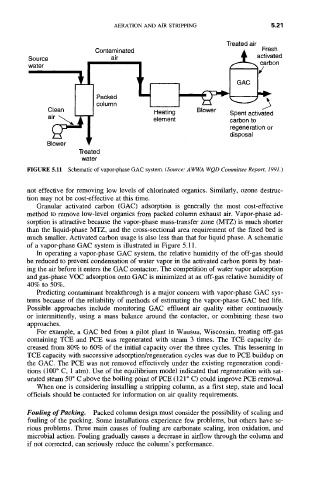

FIGURE 5.11 Schematic of vapor-phase GAC system. (Source: A WWA WQD Committee Report, 1991.)

not effective for removing low levels of chlorinated organics. Similarly, ozone destruc-

tion may not be cost-effective at this time.

Granular activated carbon (GAC) adsorption is generally the most cost-effective

method to remove low-level organics from packed column exhaust air. Vapor-phase ad-

sorption is attractive because the vapor-phase mass-transfer zone (MTZ) is much shorter

than the liquid-phase MTZ, and the cross-sectional area requirement of the fixed bed is

much smaller. Activated carbon usage is also less than that for liquid phase. A schematic

of a vapor-phase GAC system is illustrated in Figure 5. l 1.

In operating a vapor-phase GAC system, the relative humidity of the off-gas should

be reduced to prevent condensation of water vapor in the activated carbon pores by heat-

ing the air before it enters the GAC contactor. The competition of water vapor adsorption

and gas-phase VOC adsorption onto GAC is minimized at an off-gas relative humidity of

40% to 50%.

Predicting contaminant breakthrough is a major concern with vapor-phase GAC sys-

tems because of the reliability of methods of estimating the vapor-phase GAC bed life.

Possible approaches include monitoring GAC effluent air quality either continuously

or intermittently, using a mass balance around the contactor, or combining these two

approaches.

For example, a GAC bed from a pilot plant in Wausua, Wisconsin, treating off-gas

containing TCE and PCE was regenerated with steam 3 times. The TCE capacity de-

creased from 80% to 60% of the initial capacity over the three cycles. This lessening in

TCE capacity with successive adsorption/regeneration cycles was due to PCE buildup on

the GAC. The PCE was not removed effectively under the existing regeneration condi-

tions (100 ° C, 1 atm). Use of the equilibrium model indicated that regeneration with sat-

urated steam 50 ° C above the boiling point of PCE (121 ° C) could improve PCE removal.

When one is considering installing a stripping column, as a first step, state and local

officials should be contacted for information on air quality requirements.

Fouling of Packing. Packed column design must consider the possibility of scaling and

fouling of the packing. Some installations experience few problems, but others have se-

rious problems. Three main causes of fouling are carbonate scaling, iron oxidation, and

microbial action. Fouling gradually causes a decrease in airflow through the column and

if not corrected, can seriously reduce the column's performance.