Page 136 -

P. 136

7.2 CHAPTER SEVEN

Rectilinear

flow/ Skirt

Influent CE ] // ~ | Effluent ~ ~

• I ~E3 ' Tank wall~/SS~ Effluent

Effluent \\1 ~ ~

launder , ~ ,"-...._ .j

(A) Rectangular settling tank, rectilinear flow Launder

~ j Launder ~, Influent

~

~/on~'-j "~u~)~l'~'~'~~Effluent (C) Peripheral--feed settling tank, spiralflow

Distributi / ~',~ /aunder-

well ~

Distribution

Effluent

~, Influent well /.~,(,~k,

(B) Center-feed settling tank, source flow

~ Effl,uent :.

U

Influent

(D) Peripheral-feed settling tank, radial flow (E) Square settling tank, radial flow

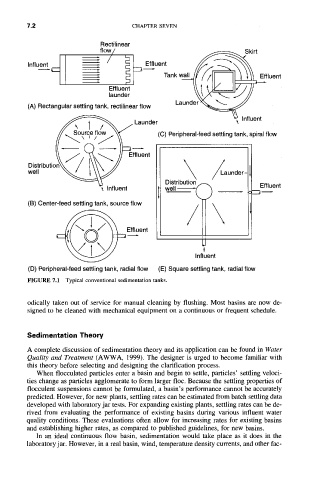

FIGURE 7.1 Typical conventional sedimentation tanks.

odically taken out of service for manual cleaning by flushing. Most basins are now de-

signed to be cleaned with mechanical equipment on a continuous or frequent schedule.

Sedimentation Theory

A complete discussion of sedimentation theory and its application can be found in Water

Quality and Treatment (AWWA, 1999). The designer is urged to become familiar with

this theory before selecting and designing the clarification process.

When flocculated particles enter a basin and begin to settle, particles' settling veloci-

ties change as particles agglomerate to form larger floc. Because the settling properties of

flocculent suspensions cannot be formulated, a basin's performance cannot be accurately

predicted. However, for new plants, settling rates can be estimated from batch settling data

developed with laboratory jar tests. For expanding existing plants, settling rates can be de-

rived from evaluating the performance of existing basins during various influent water

quality conditions. These evaluations often allow for increasing rates for existing basins

and establishing higher rates, as compared to published guidelines, for new basins.

In an ideal continuous flow basin, sedimentation would take place as it does in the

laboratory jar. However, in a real basin, wind, temperature density currents, and other fac-