Page 131 -

P. 131

6.22 CHAPTER SIX

poses. Slots should be staggered to prevent short-circuiting. Normally the floors of hy-

draulic flocculation basins slope toward the discharge end to facilitate cleaning and to

provide tapered energy.

Generally, flocculation basins are designed to be approximately the same depth as the

adjacent clarifier.

End Baffles. Most flocculator systems require an end baffle between the flocculation

zone and the clarifier, or some provision to prevent residual energy from the flocculation

process from being transferred to the clarification stage. These baffles also minimize short-

circuiting and reduce the effects of water temperature changes.

End baffles may be designed on the same basis as compartmentalization baffles de-

scribed above. End baffles should not provide a barrier to removing sludge when the floc

basin is cleaned, and limited openings in the bottom of the baffle are appropriate. Simi-

larly, a small submerged section at the top of the baffle will allow scum to pass down-

stream.

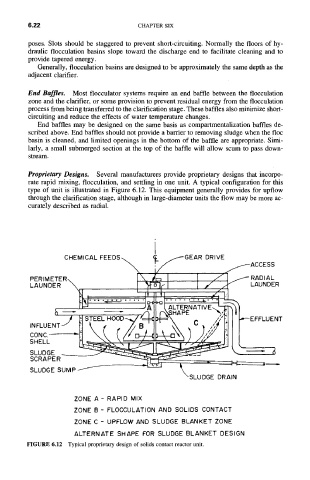

Proprietary Designs. Several manufacturers provide proprietary designs that incorpo-

rate rapid mixing, flocculation, and settling in one unit. A typical configuration for this

type of unit is illustrated in Figure 6.12. This equipment generally provides for upflow

through the clarification stage, although in large-diameter units the flow may be more ac-

curately described as radial.

PERIMETER\ I\ ~/~ I ,-/I /RADIAL

LAUNDER \ I 'yF~rl I / .KLAUNDER

• ~''" " ....... jAO-+ 31AI'TERNATI~/E~

tl " " /q I r-'N~HAPE ~'I,') I tl

/ 1-.1 STEEL HOOD---~/I==~ ==~\ C ,ql~[ [ I~--EFFLUENT

.N~LOENTI r.I ~, J,B ')' ,~ ",'// lil ll

CONC-- "i % OX~ ,,

//°?4

•

~~..-~-~--

SLUDGE ~ ~ '~ =

SCRAPER - - ~'~:~ ~ - ~ . ~ , .

SLUDGE SUMP -"I ~X'XSLUDGE DRAIN

ZONE A- RAPID MIX

ZONE B - FLOCCULATION AND SOLIDS CONTACT

ZONE C - UPFLOW AND SLUDGE BLANKET ZONE

ALTERNATE SHAPE FOR SLUDGE BLANKET DESIGN

FIGURE 6.12 Typical proprietary design of solids contact reactor unit.