Page 126 -

P. 126

MIXING, COAGULATION, AND FLOCCULATION 6.17

CHLORINE FEED

PLANT INLET PIPE

2 MIXING PUMPS

COAGULANT CHEMICAL FEED

MIXING ZONE "-~'--

G = I000 SEC-I _L..__

L

WEIRS TO FLOCCULATION~ / / ~TAPERED CHANNELS

B A S I N ~ L~____.. V:0.35 M/S MAX.

FLOCCULATION DEPARTMENTS(4) ~ REEL FLOCCULATOR TYI~

G MAX. 50 SEC. "J (4 EA. BASIN)

el.

BAFFLES "u.

(TYR) r,-

>

CLARIFIERS

CLARIFIERS

SEE DESIGN CRITERIA TABLE 5.2

HORIZONTAL PADDLE [ REEL') FLOCCULATORS

TWO BASIN DESIGN, FOUR COMPARTMENTS

EA. BAS[N BAFFLED DESIGN.

SCALE 0 ?- 4 6 8 I0 20 METERS

i

0 IO 20 30 40 50 FEET

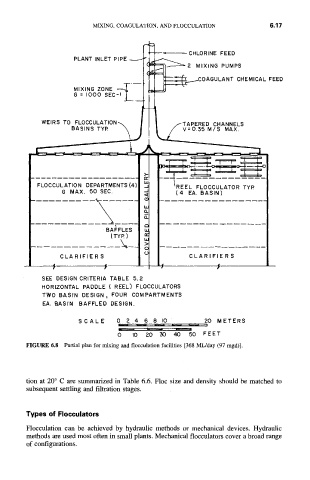

FIGURE 6.8 Partial plan for mixing and flocculation facilities [368 ML/day (97 mgd)].

tion at 20 ° C are summarized in Table 6.6. Floc size and density should be matched to

subsequent settling and filtration stages.

Types of Flocculators

Flocculation can be achieved by hydraulic methods or mechanical devices. Hydraulic

methods are used most often in small plants. Mechanical flocculators cover a broad range

of configurations.