Page 174 -

P. 174

CLARIFICATION 7.37

...... ~pressor

Pac~

Satur~

Flocculator

RHn~rRkirnmer Design

(10%)

:lecycle

)ump

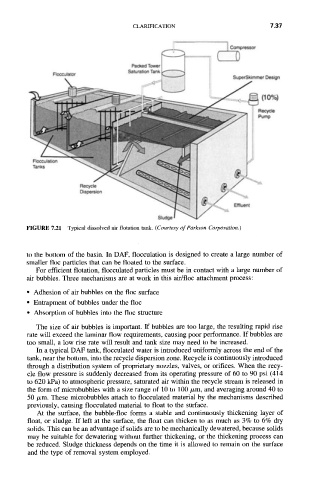

FIGURE 7.21 Typical dissolved air flotation tank. (Courtesy of Parkson Corporation.)

to the bottom of the basin. In DAF, flocculation is designed to create a large number of

smaller floc particles that can be floated to the surface.

For efficient flotation, flocculated particles must be in contact with a large number of

air bubbles. Three mechanisms are at work in this air/floc attachment process:

• Adhesion of air bubbles on the floc surface

• Entrapment of bubbles under the floc

• Absorption of bubbles into the floc structure

The size of air bubbles is important. If bubbles are too large, the resulting rapid rise

rate will exceed the laminar flow requirements, causing poor performance. If bubbles are

too small, a low rise rate will result and tank size may need to be increased.

In a typical DAF tank, flocculated water is introduced uniformly across the end of the

tank, near the bottom, into the recycle dispersion zone. Recycle is continuously introduced

through a distribution system of proprietary nozzles, valves, or orifices. When the recy-

cle flow pressure is suddenly decreased from its operating pressure of 60 to 90 psi (414

to 620 kPa) to atmospheric pressure, saturated air within the recycle stream is released in

the form of microbubbles with a size range of 10 to 100/xm, and averaging around 40 to

50/xm. These microbubbles attach to flocculated material by the mechanisms described

previously, causing flocculated material to float to the surface.

At the surface, the bubble-floc forms a stable and continuously thickening layer of

float, or sludge. If left at the surface, the float can thicken to as much as 3% to 6% dry

solids. This can be an advantage if solids are to be mechanically dewatered, because solids

may be suitable for dewatering without further thickening, or the thickening process can

be reduced. Sludge thickness depends on the time it is allowed to remain on the surface

and the type of removal system employed.