Page 206 -

P. 206

HIGH-RATE GRANULAR MEDIA FILTRATION 8.25

1 ~t- ~ _ ~,t ...... J I ~_ ....... I ....... I ....... I1-l

-~J-i!q I~I °oM .... o .............. .. -,

___~,jL--:J ",':':-" :,': I ~:, 1 "°.~.W;~'P%.": Tw"N T,L. 0...

•

I 2 ~ II ~("~11 I -+ GROUT

: '~'--.~/

IF- -1 ,°,A° ....... ON ........

COMPENSATING LATERAL ~'~'~

-,..<

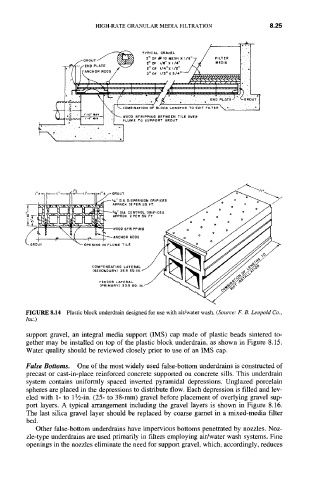

FIGURE 8.14 Plastic block underdrain designed for use with air/water wash. (Source." F. B. Leopold Co.,

Inc.)

support gravel, an integral media support (IMS) cap made of plastic beads sintered to-

gether may be installed on top of the plastic block underdrain, as shown in Figure 8.15.

Water quality should be reviewed closely prior to use of an IMS cap.

False Bottoms. One of the most widely used false-bottom underdrains is constructed of

precast or cast-in-place reinforced concrete supported on concrete sills. This underdrain

system contains uniformly spaced inverted pyramidal depressions. Unglazed porcelain

spheres are placed in the depressions to distribute flow. Each depression is filled and lev-

eled with 1- to ll/~-in. (25- to 38-mm) gravel before placement of overlying gravel sup-

port layers. A typical arrangement including the gravel layers is shown in Figure 8.16.

The last silica gravel layer should be replaced by coarse garnet in a mixed-media filter

bed.

Other false-bottom underdrains have impervious bottoms penetrated by nozzles. Noz-

zle-type underdrains are used primarily in filters employing air/water wash systems. Fine

openings in the nozzles eliminate the need for support gravel, which, accordingly, reduces