Page 207 -

P. 207

8.26 CHAPTER EIGHT

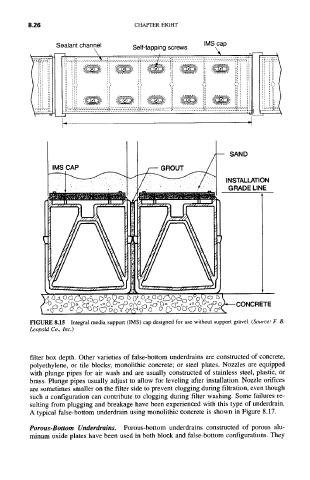

Sealant channel Self-tapping screws IMS cap

\ , \ r

iil i~:: N ~/i :~: T/,~i, il ~: il ......

iii ....... ii ....... ~,i ....... ii ...... ~! ....... ili

iill -

m

i

4

SAND

IMS CAP

INSTALLATION

GRADE LINE

~z/ ~(e eel /ze zr( i//-- ~1/ "(r eez /ze (((

;RETE

FIGURE 8.15 Integral media support (IMS) cap designed for use without support gravel. (Source." F. B.

Leopold Co., Inc.)

filter box depth. Other varieties of false-bottom underdrains are constructed of concrete,

polyethylene, or tile blocks; monolithic concrete; or steel plates. Nozzles are equipped

with plunge pipes for air wash and are usually constructed of stainless steel, plastic, or

brass. Plunge pipes usually adjust to allow for leveling after installation. Nozzle orifices

are sometimes smaller on the filter side to prevent clogging during filtration, even though

such a configuration can contribute to clogging during filter washing. Some failures re-

suiting from plugging and breakage have been experienced with this type of underdrain.

A typical false-bottom underdrain using monolithic concrete is shown in Figure 8.17.

Porous-Bottom Underdrains. Porous-bottom underdrains constructed of porous alu-

minum oxide plates have been used in both block and false-bottom configurations. They