Page 213 -

P. 213

8.32 CHAPTER EIGHT

Auxiliaries

Auxiliary equipment that the engineer must consider in filter design includes piping and

conduits supplying and removing water from the filter, valves and actuators used to con-

trol filter operations, and washwater troughs.

Conduits. Filters require hydraulic connections for influent water, filtered water, wash-

water supply, auxiliary scour, washwater drain, and (if used) a connection to allow fil-

tered water to be wasted. Influent water is usually delivered to a gravity filter through the

washwater gullet. Influent to a pressure filter is generally distributed by a tapped pipe

serving as a manifold or by a baffle plate. Influent conduits should be designed to deliver

water to the filters with as little disturbance as possible. Free fall or turbulence, which

can disturb the filter media, is undesirable. Delivering influent beneath the water surface

in the filter or baffling the incoming stream prevents media disturbance. Necessary mea-

sures depend on the control strategy used.

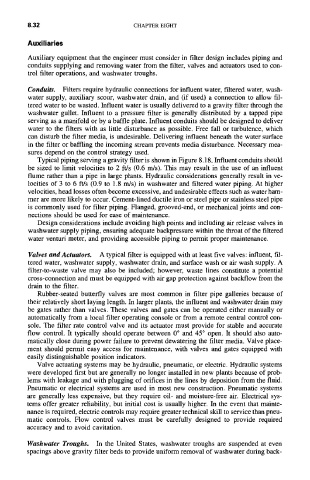

Typical piping serving a gravity filter is shown in Figure 8.18. Influent conduits should

be sized to limit velocities to 2 ft/s (0.6 m/s). This may result in the use of an influent

flume rather than a pipe in large plants. Hydraulic considerations generally result in ve-

locities of 3 to 6 ft/s (0.9 to 1.8 m/s) in washwater and filtered water piping. At higher

velocities, head losses often become excessive, and undesirable effects such as water ham-

mer are more likely to occur. Cement-lined ductile iron or steel pipe or stainless steel pipe

is commonly used for filter piping. Flanged, grooved-end, or mechanical joints and con-

nections should be used for ease of maintenance.

Design considerations include avoiding high points and including air release valves in

washwater supply piping, ensuring adequate backpressure within the throat of the filtered

water venturi meter, and providing accessible piping to permit proper maintenance.

Valves and Actuators. A typical filter is equipped with at least five valves: influent, fil-

tered water, washwater supply, washwater drain, and surface wash or air wash supply. A

filter-to-waste valve may also be included; however, waste lines constitute a potential

cross-connection and must be equipped with air gap protection against backflow from the

drain to the filter.

Rubber-seated butterfly valves are most common in filter pipe galleries because of

their relatively short laying length. In larger plants, the influent and washwater drain may

be gates rather than valves. These valves and gates can be operated either manually or

automatically from a local filter operating console or from a remote central control con-

sole. The filter rate control valve and its actuator must provide for stable and accurate

flow control. It typically should operate between 0 ° and 45 ° open. It should also auto-

matically close during power failure to prevent dewatering the filter media. Valve place-

ment should permit easy access for maintenance, with valves and gates equipped with

easily distinguishable position indicators.

Valve actuating systems may be hydraulic, pneumatic, or electric. Hydraulic systems

were developed first but are generally no longer installed in new plants because of prob-

lems with leakage and with plugging of orifices in the lines by deposition from the fluid.

Pneumatic or electrical systems are used in most new construction. Pneumatic systems

are generally less expensive, but they require oil- and moisture-free air. Electrical sys-

tems offer greater reliability, but initial cost is usually higher. In the event that mainte-

nance is required, electric controls may require greater technical skill to service than pneu-

matic controls. Flow control valves must be carefully designed to provide required

accuracy and to avoid cavitation.

Washwater Troughs. In the United States, washwater troughs are suspended at even

spacings above gravity filter beds to provide uniform removal of washwater during back-